Elsyca EPOS

Upfront evaluation of electropolishing process performances

More infoDownload file

Towards uniform metal removal rates

No CAD skills or CAD software is required.

Key Benefits

Save time, reduce stress

Designing racks and optimizing production can be done long before the parts arrive in the factory. Avoid lengthy trial-and-error runs and stressful production surprises. Buy yourself some peace of mind.

From supplier to valuable partner

Become a value-adding partner for your client … use the simulation to discuss design choices and to defend your pricing. At the same time, you build up knowledge, keep your company know-how inside the tool and enhance your overall service level.

Improved product quality

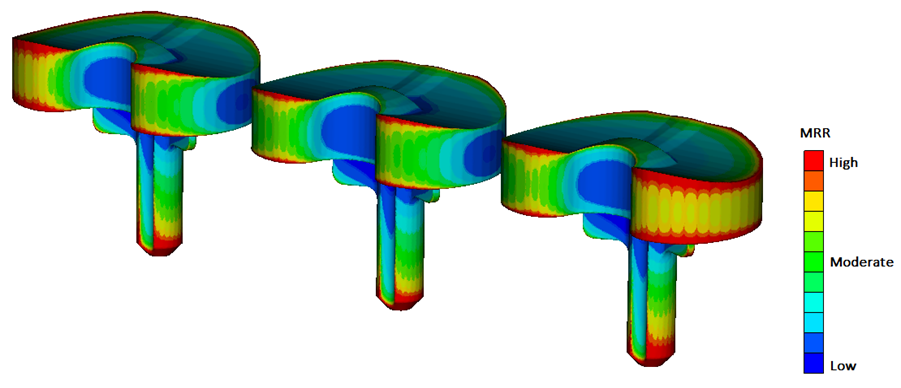

Upfront evaluation of the high and low metal remove surface areas and tooling effectivity (rack, jig, fixture, cathodes, shields) to deliver the best product quality while ensuring reproducible process results every time.

Reduce costs, save money

Avoiding expensive trial runs, no more scrap due to plating issues, maximizing part load without risking loss of quality … it all ultimately leads to higher profits for your company.

Key features

A wide range of functionalities

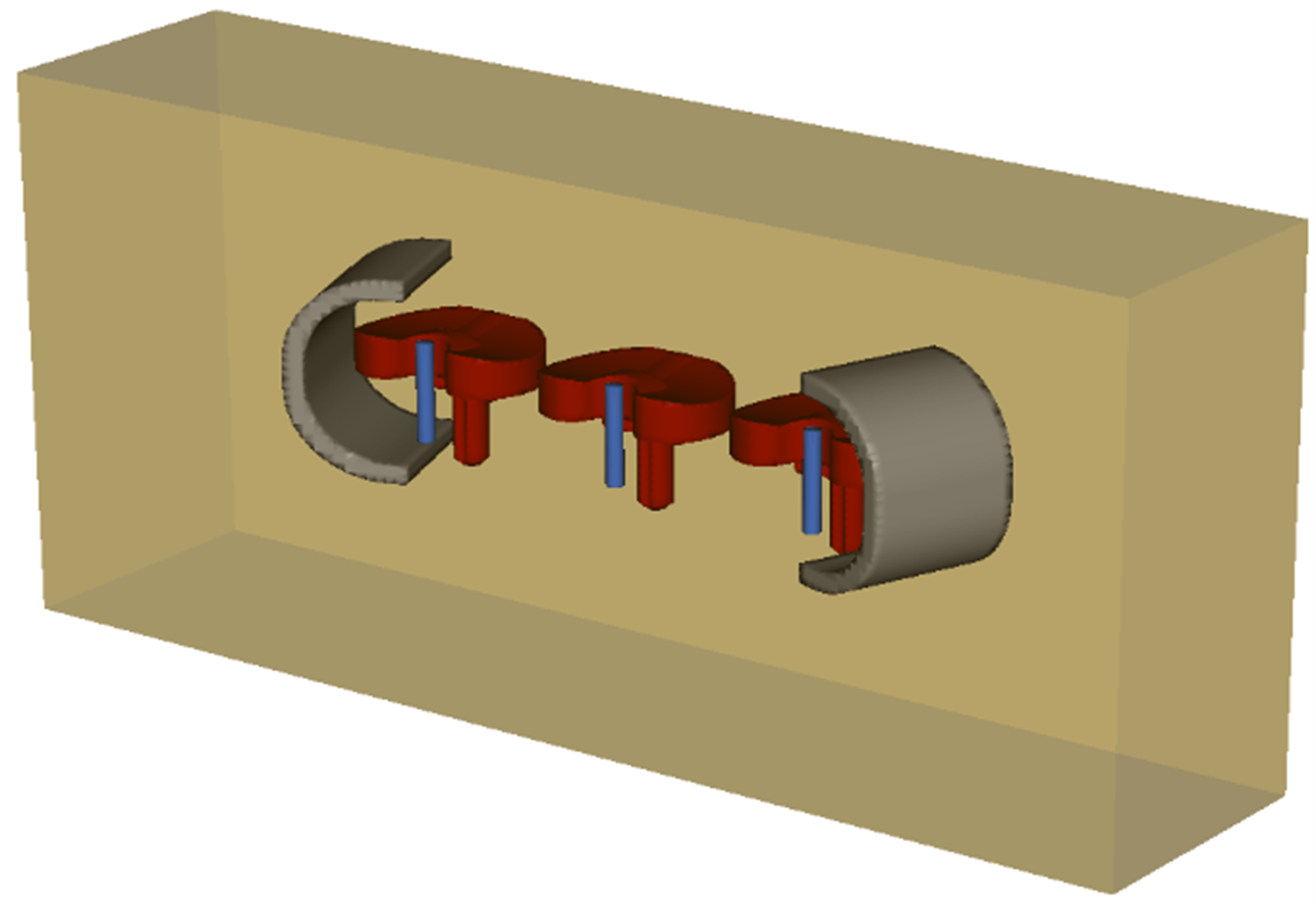

Embedded model of your plating line infrastructure

Select your ready-to-use plating line and simulate various electrochemical processes simultaneously.

From individual parts to elaborate rack arrangements

Easily manipulate parts to achieve the most efficient rack distribution configuration. Convenient verification of the plating package.

Interpret results with just a few clicks

3D color plots of layer thickness and production risk zones with embedded movie capability. 2D bar charts for efficient production variance analysis.

Optimization in just a few iterations

Optimize contact clip arrangement. (Re)configure easy way to add tooling to for your racks. Fast virtual iterations.

Convenient to share and collaborate

Automated reports are created at the end of the simulation.

3D results visualization

See and share 3D results with standalone Elsyca XPlorer viewer.

Combine and compare different projects with batch processing

A tabular overview with the key performance indicators provides a clear overview and allows the user to identify the most promising projects without the need to load this projects individually first.

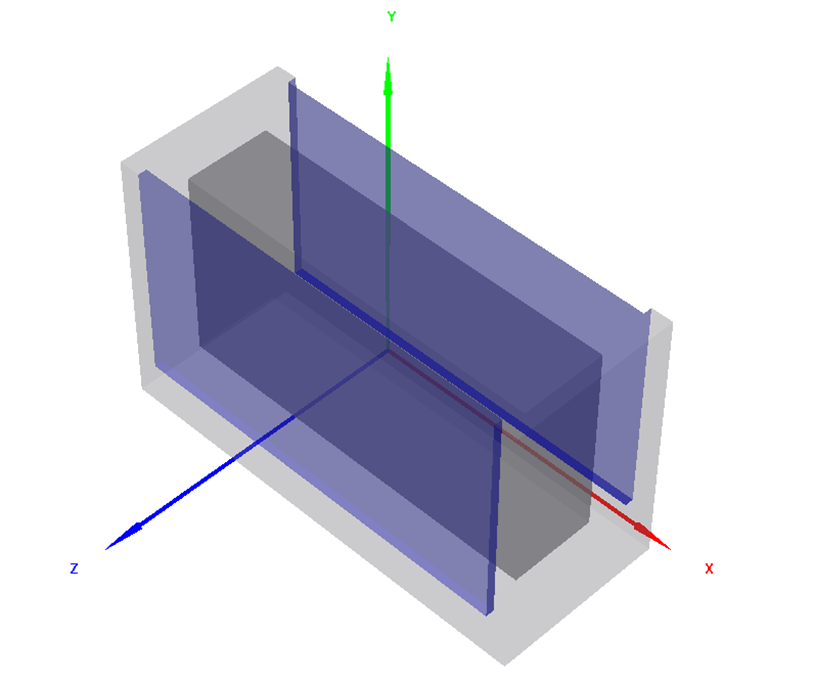

Design new tooling

Use the Basic Shapes Module to design new tooling like shields and current robbers within the tool. No need to rely on CAD tools or have CAD skills.

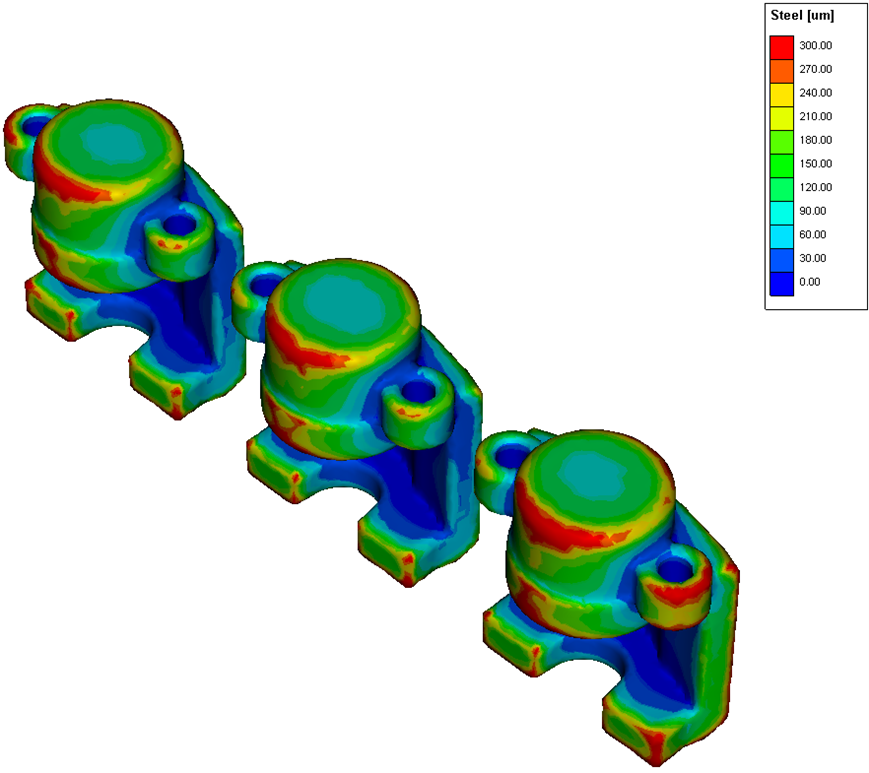

Surface offset/re-meshing

An improved surface offset/re-meshing technology has been implemented to convert STL models to valid surface models (library components). As a result, the number of elements on the surface mesh has been considerably reduced while keeping the same high quality as before.

This improved surface mesh has a drastic impact on the simulation time and memory needed to run a simulation. On average both the time it takes to complete a simulation as well as the required internal memory have been reduced with factors 4 to 5.