Storage Tanks

Holistic and non-intrusive assessment of corrosion risks to develop effective risk based inspections and avoid costly repairs

Download file

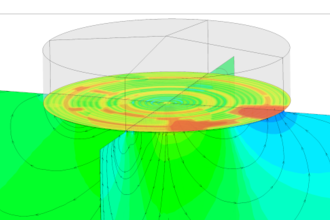

Unprecedented insights into corrosion conditions

Making the invisible visible

A turning point in corrosion risks management

The management of corrosion of storage tanks is at a turning point in history. Until now, the current practices and field measurements only provided an idea of the corrosion condition at a limited number of locations around the tank pads. With Elsyca's solutions and dedicated team of experts, asset owners have finally access to unique and unprecedented insights on the accumulated risks of internal and external corrosion conditions of tank bottom plates.

The evaluation of corrosion risks and levels, and cathodic protection systems effectiveness has never been so accurate and our digital twin approach combining field data with numerical modeling will help you to:

- quickly, accurately and proactively evaluate protection levels and corrosion status of your storage tanks;

- Implement more effective protection systems based on tank pad conditions;

- be in line with PHMSA requirements and international standards;

- lower your Cathodic Protection (CP) installation and maintenance costs;

- standardize your CP systems for future installations;

- support the development of cost-effective Risk Based Inspection (RBI) programs.

There is no other solution able to combine local environmental characteristics with tank bottom protection levels to deliver an accurate and holistic assessment of the corrosion risks. This unique combination is the only way to develop risk-based inspections programs, avoid costly repairs and extend the service life cycle of your assets.

Investing in a digital twin approach

Answering Needs

Elsyca's expertise answers all major concerns of asset owners keen to develop cost-effective inspection and maintenance programs by:

- removing subjectivity in prioritization of tank inspections (RBI programs);

- understanding of CP systems effectiveness and interactions;

- studying corrosion stop barriers via computer-aided solutions;

- considering local tank pad properties;

- meeting regulatory requirements for the full tank bottom plate.

Delivering continuous support

Our solution combines for the very first time computation, quantification, and qualification of safety and corrosion risks to deliver:

- advantageous 3D visualization of the risks and threats;

- verification of installation effectiveness and compliance prior to materials procurement;

- ability to numerically model CP systems truly adapted to your tanks and their environments;

- improved regulatory and internal company reviews and audits.

Ensuring the protection against corrosion for any tank

New tanks

Our computed-aided solutions help you to choose appropriate and effective CP systems for your new tanks:

- we gather field data and tank characteristics including foundation properties and rig walls to build a digital twin of your asset and its environment;

- we define via computer-aided design the most adequate CP system, make sure you can reuse it for future implementation using controlled material;

- we follow the construction of the designed CP system and guide you to ensure the CP system deployment is done as planned.

Existing tanks

We do review existing installations, perform risk ranking, and suggest retrofitting and adequate future systems based on:

- existing infrastructure properties and field data;

- computation of current level of CP over the entire tanks floors;

- optimized CP systems computation considering in-situ conditions.

Tank terminals

We perform the risk assessment of your entire tank terminals in order to:

- visualize the CP status over terminal plant piping and isolate areas that are not compliant;

- identify stray current influences from third party systems or the interaction between CP systems of terminal piping and tank bottoms and groundings;

- determine current and potential distributions on manifold & terminal pipelines and tanks bottoms;

- prioritize your investment when developing new CP systems.