Plate

The industry-standard solutions to control the quality of your surface finishing and plating operations.

Gain profitability by ensuring quality and efficiency of plating operations through upfront analyses

Ensure quality and efficiency

Whatever the final application, Elsyca's solutions support you to understand and control the plating parameters that drive the final product quality. Elsyca's solutions support all plating and surface finishing operations including:

- plating-on-plastics (PoP);

- corrosion-resistant coating;

- precious metal coating;

- copper and tin plating;

- PCB plating;

- electropolishing and electroforming;

- anodizing and electro-coating;

- functional and decorative surface finishing;

- reel-to-reel plating operations.

Optimize processes

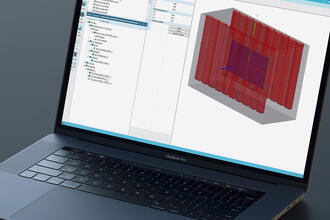

Elsyca's solutions rely on accurate 3D modeling techniques to build digital twins of the complete manufacturing process. This delivers unique insights into the efficiency of plating operations and supports designers and engineers in:

- assessing optimum configurations before the start of production;

- understanding how to deal with new innovative coatings following new regulations;

- improving final layer thickness distribution without the need for post-processing operations;

- optimizing tooling configurations and production sequences.

Save time, material, and costs

Investing in Elsyca's solutions provides companies with the possibility to look for the most effective plating and surface finishing parameters without the need to perform costly and time-demanding trials. Our solutions add virtual electrochemical experts to your company and help you to:

- design right-first-time and limit the need for trials;

- shorter your time-to-market delivery;

- reduce your total manufacturing costs;

- reduce the material waste;

- minimize your energy consumption.

How do we deliver?

Elsyca's approach

Software

Our software solutions are recognized as industry standards offering the ability to:

- perform as-is process analysis for deposit quality risk assessment;

- optimize surface finishing and plating parameters including rack layout, plating time, tooling design, imposed current,...;

- predict compliance of deposit thickness to industry standards;

- assess plating feasibility of new coatings;

- reduce operational costs.

Services

Combine Elsyca's solution deployment with guidance from our experts to:

- evaluate the performances of tooling concepts;

- develop best practices of your plating and surface finishing operations;

- troubleshoot any products defects;

- develop best-practice guidelines.

Technology Transfer

Our mission is to ensure the optimum solution for any of our users. Based on your specific application, product, and installation set-up we deliver:

- a turnkey solution containing the digital twin of your installation;

- dedicated training sessions and sharing of best practices;

- 3D numerical models containing our expertise;

- integration within existing processes

Our areas of expertise

Did not find your application?

Contact us! We can probably help you !