Elsyca AnodizingManager

Speeding-up your metal surface transformation

More infoDownload file

Anodizing of complex part designs made simple

Elsyca AnodizingManager is the state-of-the-art graphical simulation platform for analyzing the production performance and quality of anodizing processes. Simulations are executed using a virtual mock-up of your in-house anodizing line. Anodizing companies face many challenges, as increasingly complex part designs and stricter specifications on not only oxide film thickness but also pore diameter and density. Elsyca AnodizingMaster is a valuable tool capable of dealing with the most complex part designs, calculating temperature dependent results for the porous oxide film thickness, pore diameter, pore density and barrier layer thickness for every part on a rack. The benefits are tangible and proven: improve production quality, reduce time-to-market, defend production choices and pricing strategy to your clients, etc.

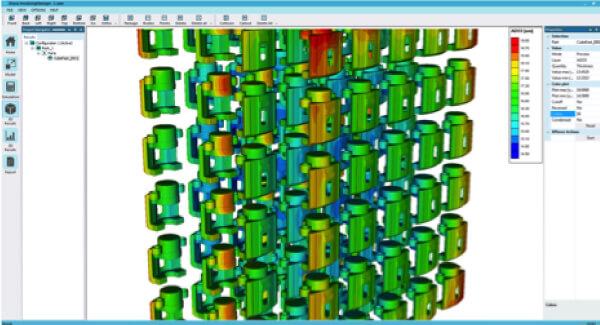

Elsyca AnodizingManager simulates the anodizing process and provides detailed information on the porous oxide film thickness distribution over the various parts on the rack while highlighting potential problem zones. Alternative part orientations and/or rack configurations can now be evaluated in only a few mouse clicks, additional tooling can be designed and its effect verified, and once the quality is optimized the rack and part lay-out is available as CAD data to start the construction of the fit-for-purpose racks … the whole process has never been more efficient!

Key Benefits

Improved Quality

Highlighting potential production issues, targeted quality tests can be done and adjustments to enhance overall quality.

Time-to-market

By simulating the anodizing process even before the first physical part, you can have the optimum rack lay-out ready in time for production kick-off.

Better profit margins

Eliminate guesswork. The simulation analysis allows you to prove the impact of production choices on pricing.

Higher customer satisfaction

All the benefits of simulation (reduced time-to-market, increased capacity, improved quality, ...) will strengthen your company image en help building excellent customer relations.

Key features

A wide range of functionalities

Prepare your model in just a few clicks

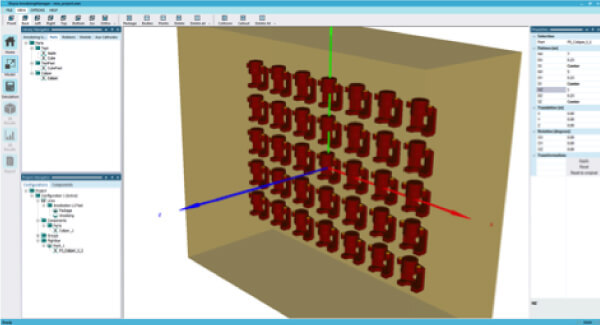

Simply export your model from your favorite CAD platform and import the STL files into Elsyca AnodizingManager. It is indeed as simple as that! In addition, easily position and automate patterning of parts on the rack.

Tailored to your infrastructure

Your real-life anodizing line is pre-configured by Elsyca

Quickly compare scenarios

Easily and quickly compare different scenarios including temperature-dependent current density, oxide film thickness distribution, and pore size and density.

Automated yet customizable reporting

Define the content of your reports based on your own KPIs.

Export your optimum configurations

Quickly generate STL file formats of the rack and part layout providing optimum results