Elsyca PlatingManager

The key to cost, quality and capacity control of your plating lines

More infoDownload file

Ingenious in its simplicity.

No CAD skills or CAD software is required.

Load and run

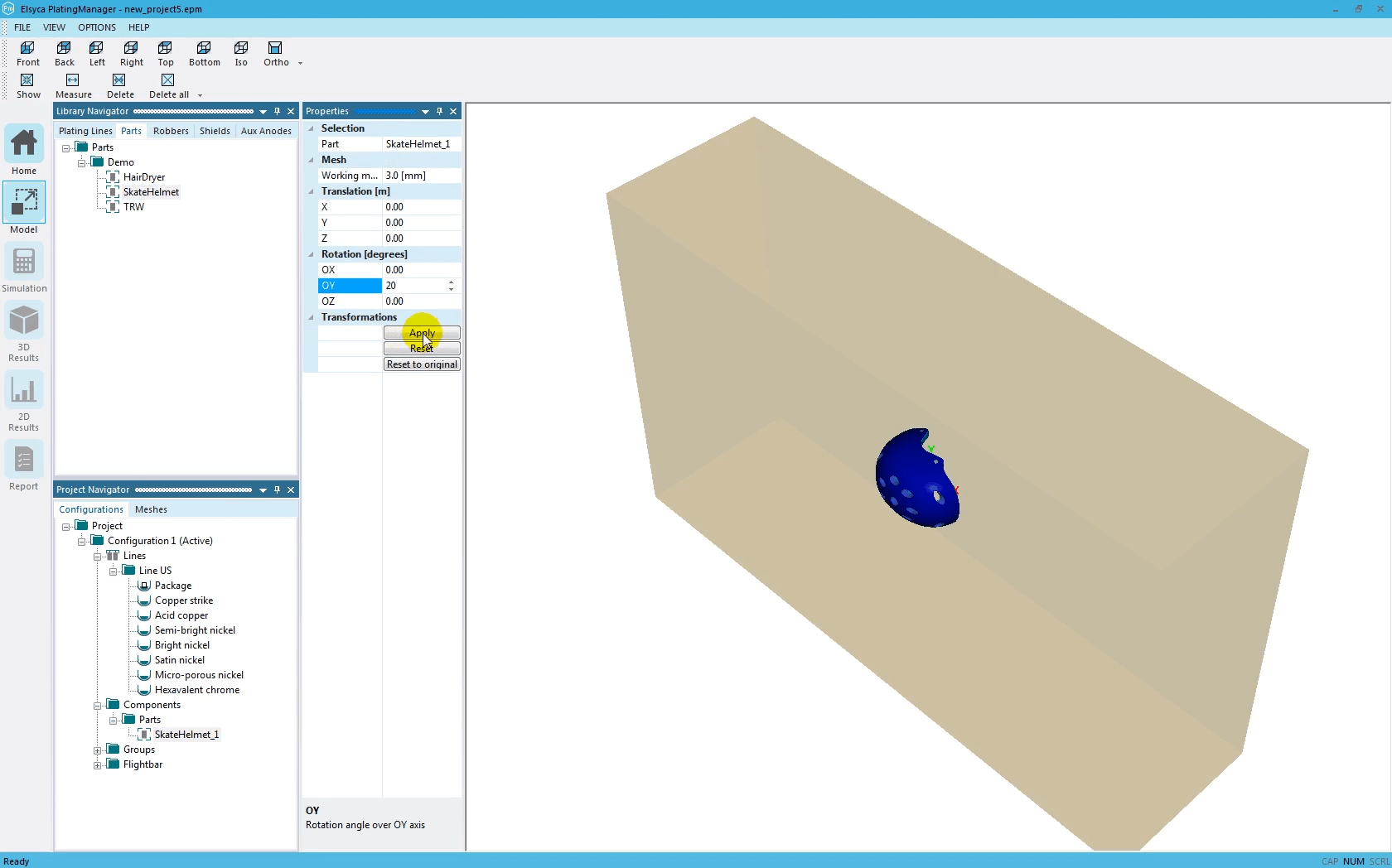

Elsyca PlatingManager provides detailed information on the plating performance for all parts on the rack and fully supports the production part approval process. It comes with a pre-configured model of your actual plating line infrastructure (the so-called "digital twin"). As a user, you just load the CAD model of the part, set the process parameters, and press the simulation button. It is really that simple!

Approve your process

Elsyca PlatingManager supports the production part approval process and is the right tool for both the production engineer at the plating shop as well as the program or quality manager at the OEM or tier 1 supplier. The software was developed in collaboration with the plating industry and has evolved to become a standard within the plating industry.

What distinguishes Elsyca PlatingManager from any other solution on the market

The fundamental reasons that make this technology so unique

Key Benefits

Save time, reduce stress

Designing racks and optimizing production can be done long before the parts arrive in the factory. Avoid lengthy trial-and-error runs and stressful production surprises. Buy yourself some peace of mind.

From supplier to valuable partner

Become a value-adding partner for your client … use the simulation to discuss design choices and to defend your pricing. At the same time you build up knowledge by using intelligent simulation software, enabling you to enhance your overall service level.

Improved product quality

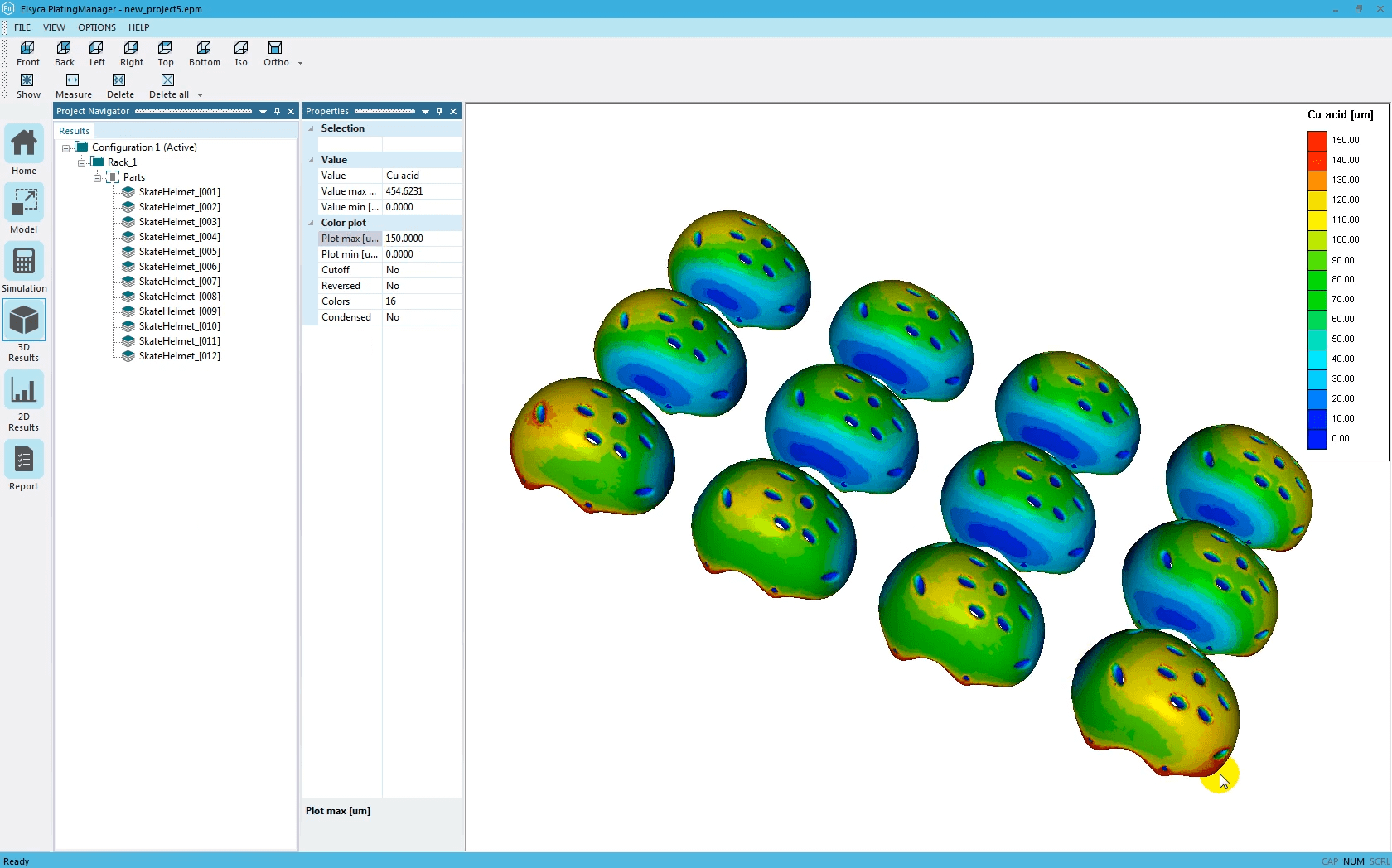

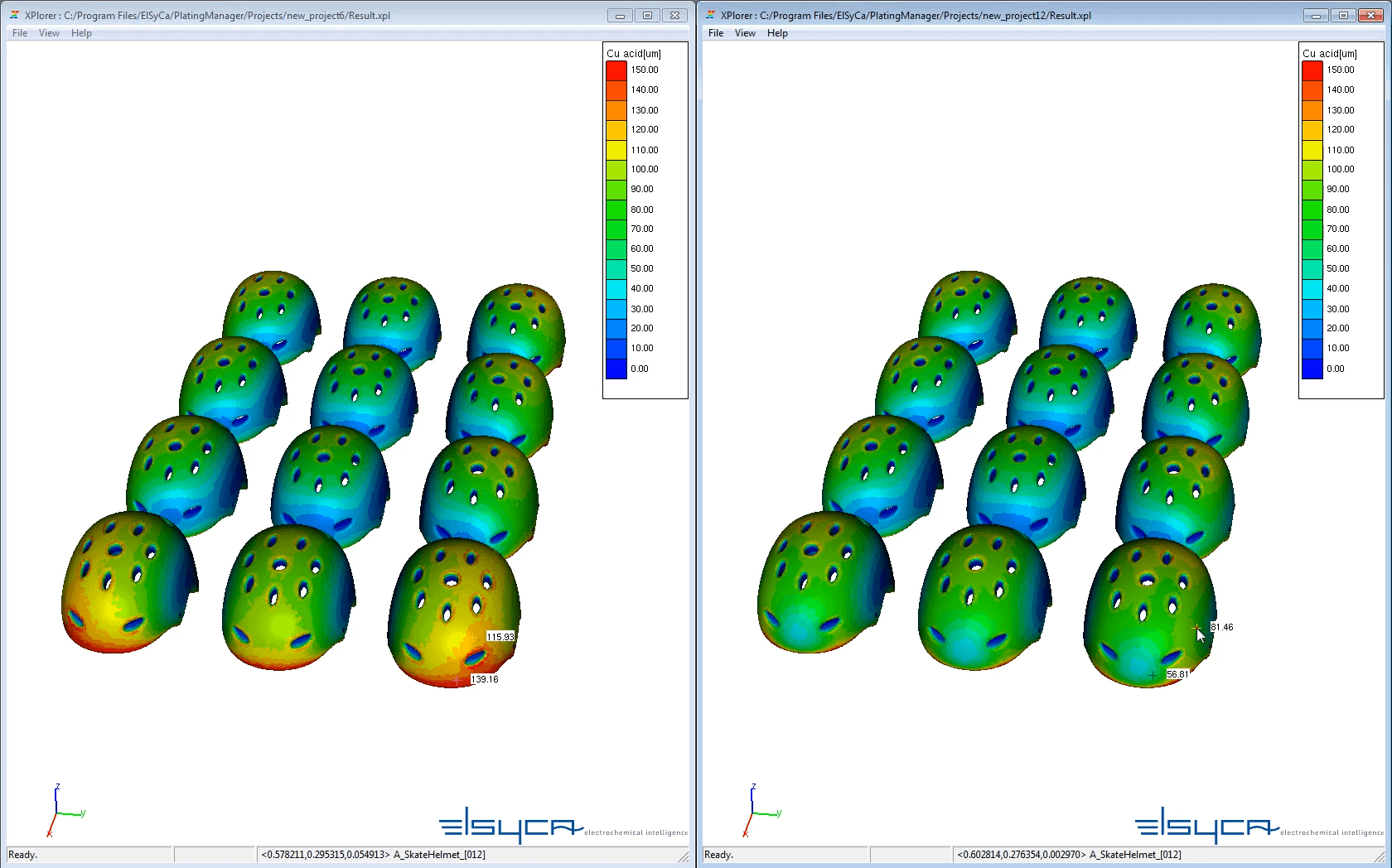

Visualize upfront the risk zones (lack of coverage, burning, nodular growth, …) on the part and adapt your part load, production parameters or rack design accordingly. An on-time delivery of quality-plated parts leads to a satisfied customer!

Reduce costs, save money

Avoiding expensive trial runs, no more scrap due to plating issues, maximizing part load without risking loss of quality … it all ultimately leads to higher profits for your company.

Key features

A wide range of functionalities

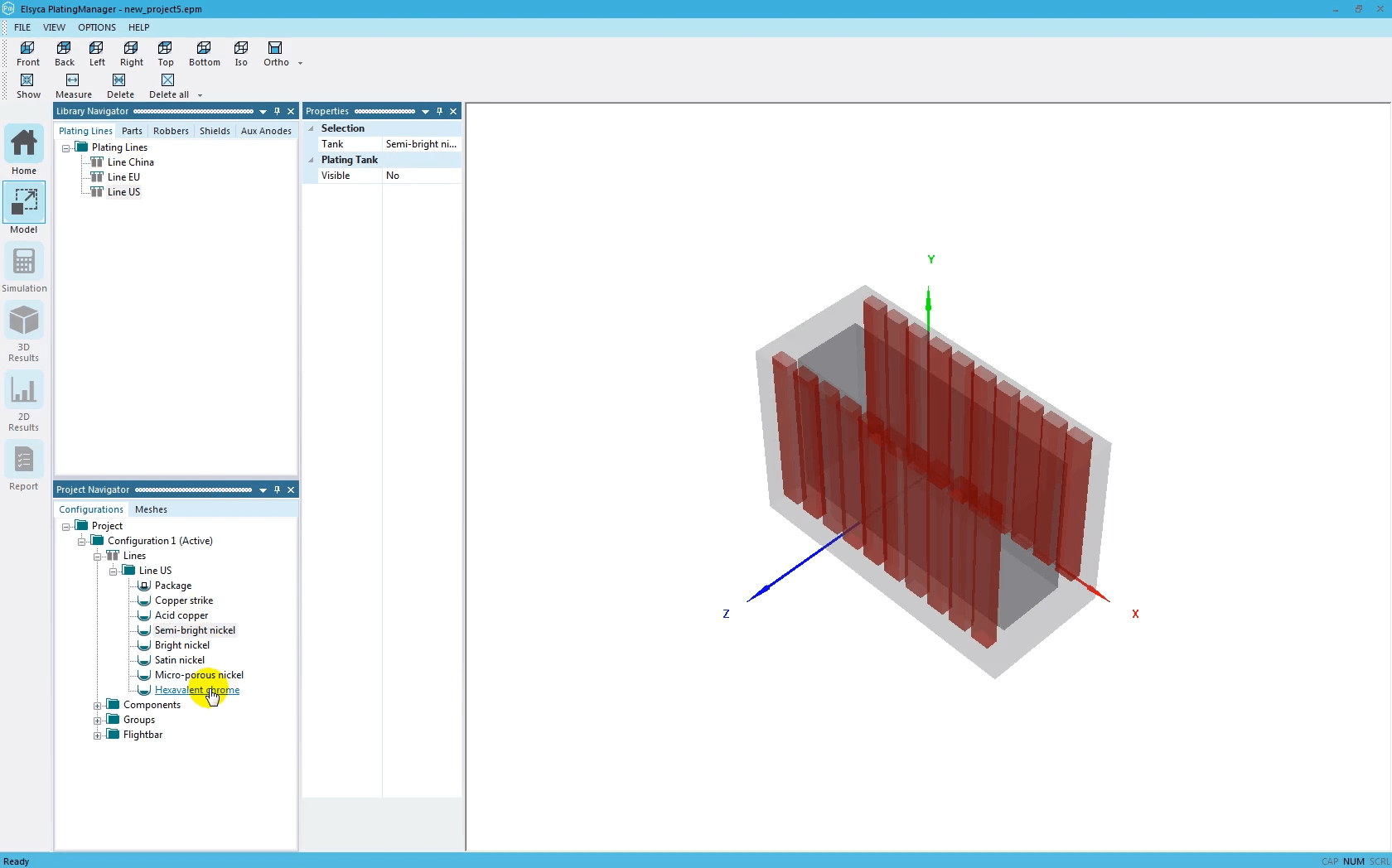

Embedded model of your plating line infrastructure

The digital twin(s) of your plating line(s) are embedded in the software. Simply select the plating line you need for your upfront analysis and start your simulations!

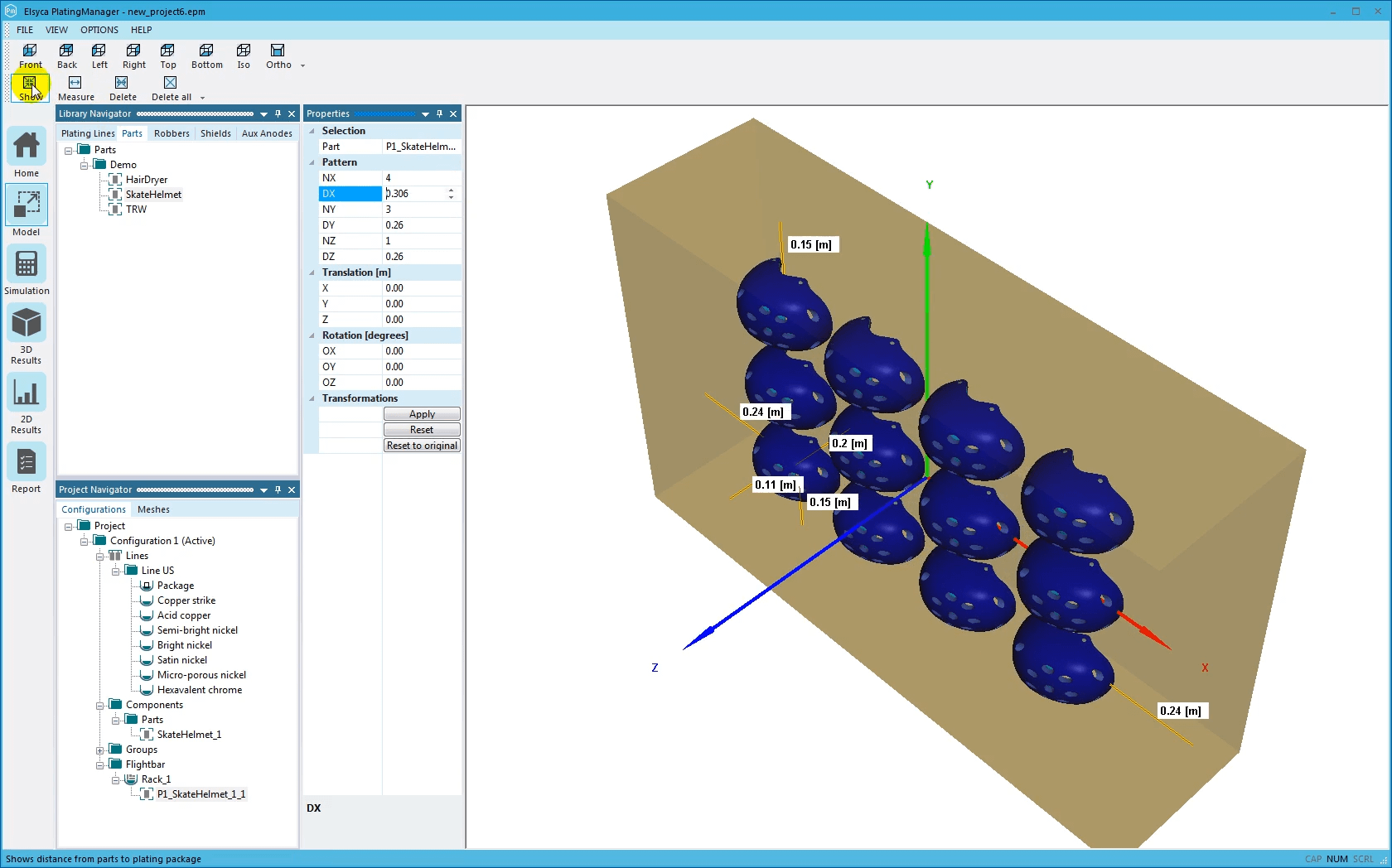

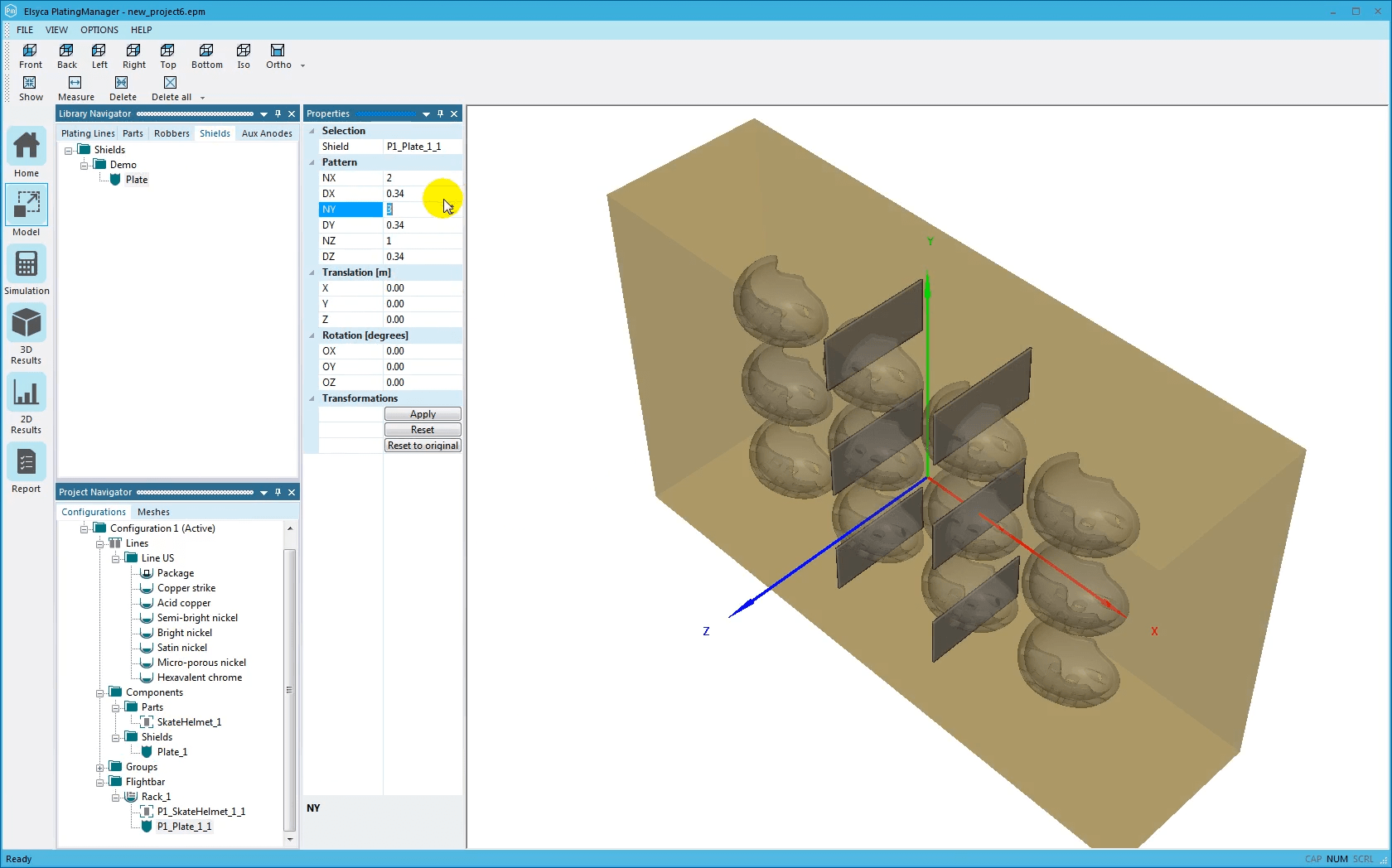

From individual parts to elaborate rack arrangements

Easily distribute parts to achieve the most efficient rack configuration. Convenient verification of the plating package.

Interpret results with just a few clicks

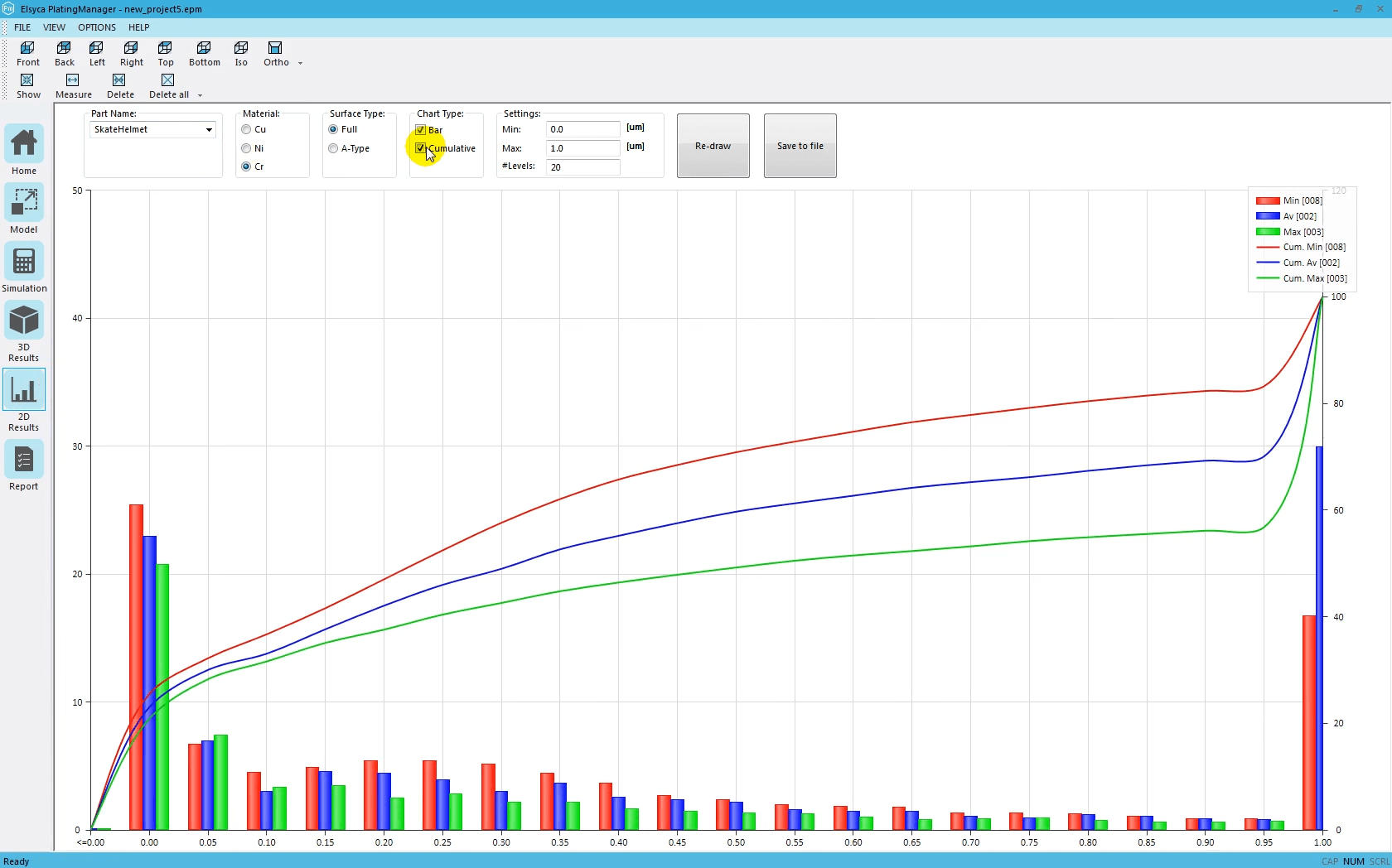

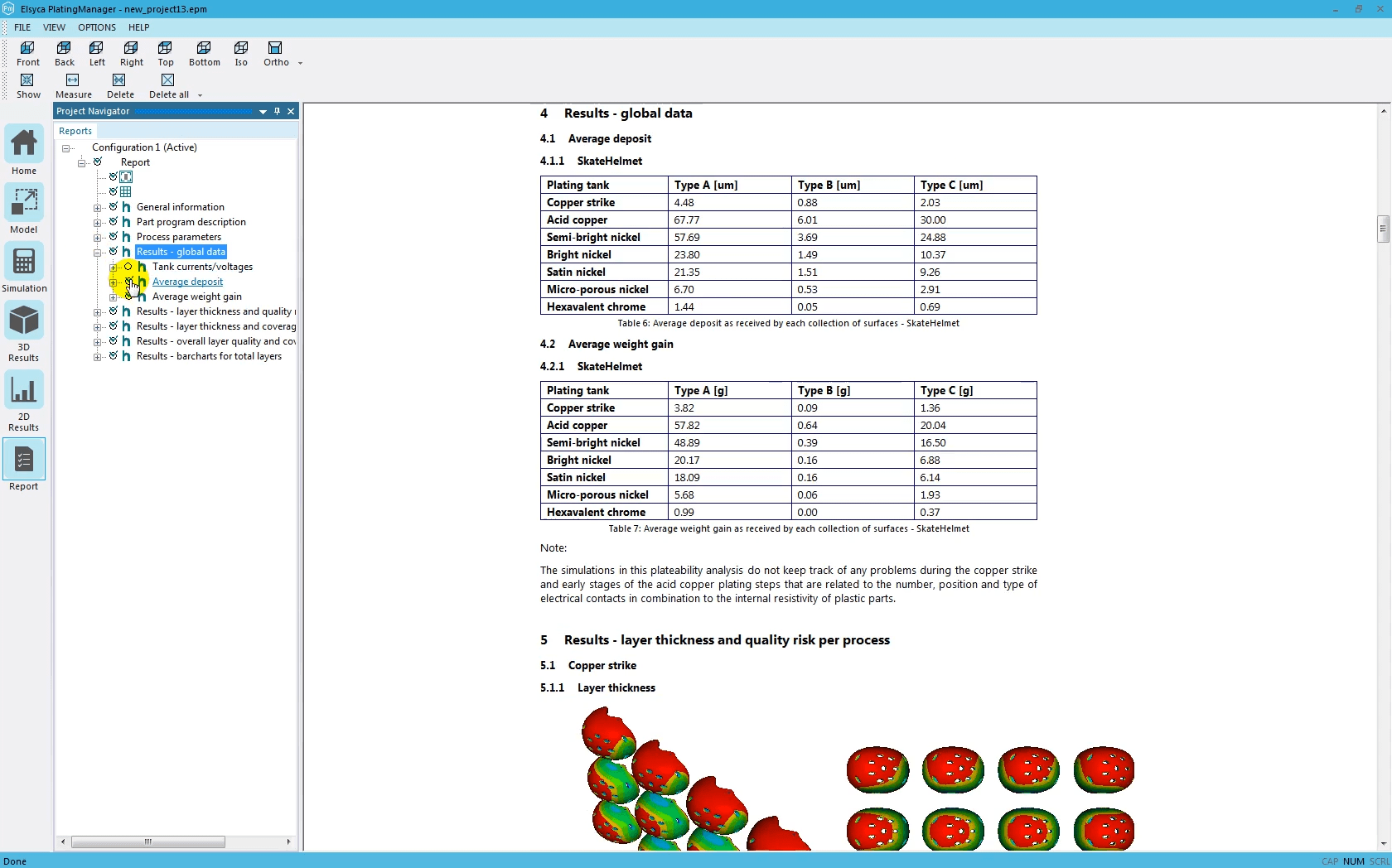

3D color plots of layer thickness and production risk zones with embedded movie capability. 2D bar charts for efficient production variance analysis.

Optimization in just a few iterations

Optimize contact clip arrangement, easily (re)configure rack arrangement and add new tooling to assess plating efficiency.

Convenient to share and collaborate

Automated reports are created at the end of the simulation. Configurations can also be directly imported in the SolidWorks environment.

3D results visualization

3D results can be post-processed and shared 3D results with the standalone Elsyca XPlorer viewer.

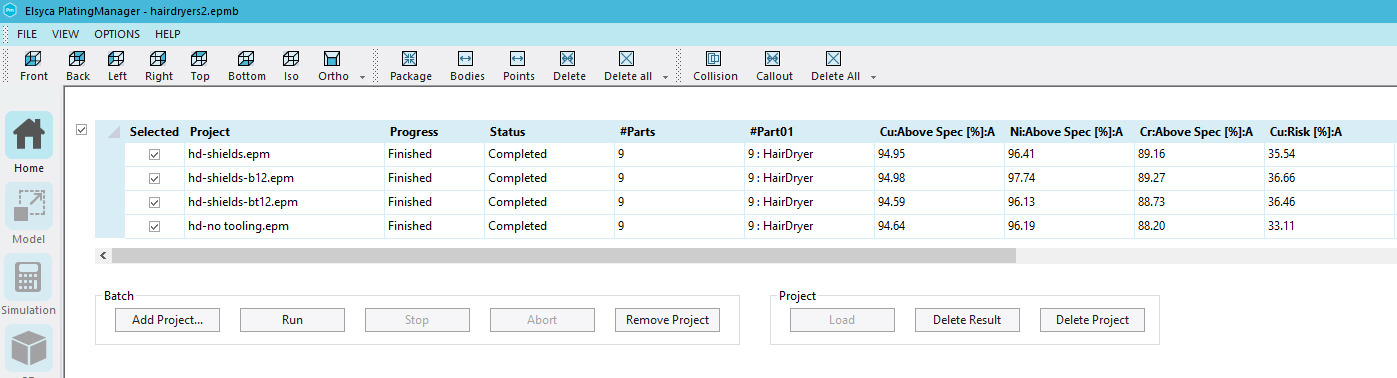

Combine and compare with batch processing

A tabular overview with key performance indicators provides a clear overview allowing users to identify the most promising projects without the need to load projects one by one.

Design new tooling

Use the Basic Shapes Module to design new tooling like shields and current robbers within the tool. No need to rely on CAD tools or have CAD skills.

Use of P-points

This module allows the automatic creation of P-points (probe points) on your master model. Communication of plating performance between supplier and OEM now becomes even more efficient!

Zero offset on non-manifold/watertight STL models

This feature allows creating a zero-offset surface mesh for certain STL models that are non-manifold (or watertight). With the zero-offset meshing, you are guaranteed to use the highest geometrical resolution of your model in the simulations!

Surface offset/re-meshing

An improved surface offset/re-meshing technology has been implemented to convert STL models to valid surface models (library components). As a result, the number of elements on the surface mesh has been considerably reduced, and both the time it takes to complete a simulation and the required internal memory have been reduced with factors 4 to 5.

Consideration of liquid drag and gas traps

Compute directly from Elsyca PlatingManager the risk of having liquid dragged outside the tank and that can contaminate subsequent plating tanks a well as the location of gas bubbles trapped inside cavities risking to reduce local electrolyte conductivity.

A special feature in the spotlight:

Use of P-points

This module allows creating P-points (probe points) on your master model. These P-points can be created by clicking on the master model in the graphical window or by importing files with the label and coordinates of the P-points.

After simulations have finished, a user-friendly tabulated file with all P-point results is created per part program, allowing easy post-processing and comparison of results. The 3D Results view displays the simulation results in the P-points for the complete rack or for the key parts only.

In addition to that, Elsyca XPlorer has been modified to import these tabulated files and display the P-point results with a single mouse click!

Communication of plating performance between supplier and OEM now becomes even more efficient!

Designing for quality: the Ford way

LaRon Michelle Brown, Technical Specialist at Ford Motor Company, tells about her experience with Elsyca PlatingManager to enhance their production process.

Using Elsyca as an indicator of a Tier(1)s capability to plate a new design concept, while providing recommendations to the studio to design a manufacturable feasible component, is truly beneficial in efforts to mitigate warranty.

User Case: Joe Randazzo. , Automotive Plating Specialist at Atotech

“Elsyca PlatingManager offers plating companies the ability to improve performance, speed-up part development and save money”

“When at General Motors Corporation and putting Elsyca to the challenge of coming up with a simulation package that was simple enough for anyone to use, I was not certain of what the outcome would be. But, I am very impressed with the final product personally. The ability for anyone without strong FEA, CAE or strong plating design experience to now be able to simulate plating thickness on a single part or full carry bar is powerful stuff. Any time you can take the guess work out of part arrangement or rack design it is very helpful from the very start of any part design considerations.

It offers plating companies the ability to improve performance, speed-up part development and save money. Growth, rapid design change-over and time pressures in the automotive industry are making it difficult to keep up without computer aided assistance like the Elsyca PlatingManager can offer. It takes years of individual experience to even approach the type of precision in evaluating racking scenarios that the Elsyca PlatingManager can do in a matter of minutes. I believe the software will be good for both OEM and plating companies alike.”

Audi acquires Elsyca PlatingManager for design validation of decorative trim components

More and more automotive suppliers embrace the Elsyca PlatingManager software to optimize their electroplating processes. These companies step up the co-operation with their customers by sharing the simulation reports and deciding together on the compromise between cost and quality of the plating process.

Audi joins the rank of OEMs that use Elsyca PlatingManager in view of design optimization and validation with respect to the electroplating process. Supported by the enthusiastic response of early customers, Elsyca PlatingManager has already positioned itself as the standard for this industry.