Discover our complete solutions portfolio covering Cathodic Protection and Corrosion management - PCB design and plating - Functional and decorative plating - Electrocoating - Acoustics

Discover Protect

Elsyca V-PIMS

A revolution in digital PIMS combining Pipeline Corrosion Integrity Management System (PIMS) and computational modeling capabilities

Elsyca IRIS

Deep analysis of AC threats supporting efficient mitigation systems computer-aided design

Elsyca CatPro

Graphical simulation platform for cathodic protection and DC stray current analysis of pipeline networks

Elsyca CPManager

3D CAD-based software simulation platform for the computer-aided design and analysis of cathodic protection installations

Elsyca ACTA

Unique solution offering accurate, disambiguated, and tailored risk ranking report of pipeline networks

Plate

Elsyca PlatingManager

Leverage a digital twin of your plating line to predict plating performance and increase manufacturing capacity

Elsyca PCBBalance

The world’s only PCB DFM software that applies automated and optimized copper balancing to your PCB design and panel layout.

Elsyca PCBPlate

State-of-the-art graphical simulation platform for enhancing the plating performance of your PCB panel and pattern plating processes.

Elsyca ECoatMaster

CAD independent software platform for the simulation of the automotive electrocoating process of a body-in-white (BIW).

Elsyca EPOS

Simulate the performances of electropolishing processes based on a virtual mock-up of the electropolishing cell.

Elsyca AnodizingManager

State-of-the-art graphical simulation platform for analyzing the production performance and quality of anodizing processes.

Innovate

Elsyca CorrosionMaster

CorrosionMaster identifies corrosion hot spots and predicts corrosion rates, enabling engineers to look at alternative material combinations and/or coating systems, or investigate corrosion-mitigating measures.

Elsyca LeakageMaster

Improve vehicles interior acoustic comfort by performing upfront virtual smoke tests.

Elsyca MeshingMaster

Automatically creates meshes for a variety of applications such as acoustics, CFD, thermal analysis, etc

Elsyca XPlorer

Interactive simulation results viewer for Finite Elements results

Elsyca XPlorer3D

Analyze, Understand and Get Immersed in your results

PCB 电镀

通过成熟和准确的仿真解决方案助力电流的设计和生产流程优化

优化成本、质量、上市时间和生产能力

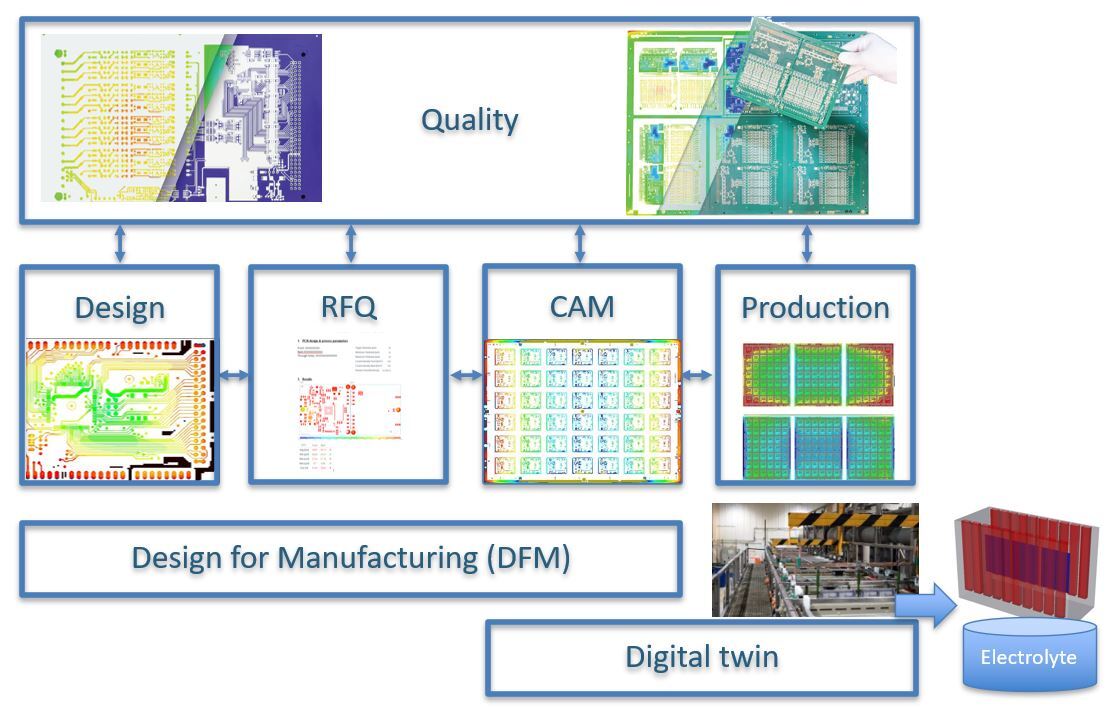

确保从设计到生产整个周期的质量

整个PCB市场都面临着压力

- 由于必须在较小的基底面上安置更多的元件,迫使PCB设计者减少安全边际量,导致出现一些潜在的阻抗或电流量问题。

- 半导体加工厂在受到电镀工艺本身特性的约束的同时又被要求在最短的时间内须以最低的成本提供高质量的产品。

Elscya 的解决方案通过以下方式支持使得PCB行业的所有相关者都受益:

- 尽可能更早地发现的生产制程中潜在质量问题;

- 避免将设计端的失误带入到进入生产;

- 减少设计迭代,加快上市时间;

- 确保零件的生产符合规格;

- 合理化铜箔层厚度分布;

- 优化生产能力并降低成本.

我们所提出的准确而快速的电镀模拟解决方案填补了现有工具之间的空缺,并且独创性的为整个PCB产业链提供全面的质量控制。

了解新的预测性工程建模解决方案是如何改变整个PCB行业的

加快行业快速发展的关键在于追求提高产品质量的一致性

计算机辅助工程的解决方案有利于PCB设计和生产流程的扩展

PCB 设计工程师

设计走上制造成功性的正轨

- 前期的设计可制造性检查,不需要了解任何电镀或产品特点、作用和优点方面的细节;

- 检测您的设计对铜层厚度的影响;

- 优化您的PCB设计以利于制造;

- 依靠添加辅助铜线平衡,优化电流分布.

计算机辅助制造CAM工程师

规划的PCB Panel的布局能在制造在质量和成本之间达到最佳状态平衡

- 让每个CAM工程师都成为电镀专家;

- 在几分钟内识别出所有的电镀质量突出问题;

- 充分利用独特的嵌入式辅助铜线的设计排布.

工艺工程师

微调生产设置,以提供一致的质量

- 在第一块Panel制成之前就能发现并解决电镀问题;

- 在几分钟内识别出表面和孔内的质量突出问题;

- 预先获取在整个飞把上的产品最终的质量信息.

在每个生产环节上的质量控制

在设计阶段对电镀和铜平衡的考量是至关重要的

Patrice Chetanneau

PCB Technologies Senior Expert at Safran

在过去两三年我们与PCB制造商,尤其是法国PCB行业开展的工作中,我们越来越意识到,要想避免对制造产量和质量的担忧,而导致的成本、延误和原材料浪费的问题,就要优化PCB内外层的铜线的布局.

所有的行业面临相同的问题,从快速消费品到汽车行业,尤其是在价格处低位时。不幸的是,大多数设计师无法理解设计端和制造端所关注和所擅长的问题之间存在的差异.

8年来,我们一直在内部努力开发一种计算机辅助的PCB设计工具,有利于我们能够做一些更有趣的研发。事实上,Elsyca软件走在了前列,原因在于他们将导通孔和孔之间镀层也考虑在内,这是尤为重要的。我们对此十分感兴趣且非常希望能够直接在PCB设计工具中动态地用Elsyca的放置分析我们的PCB.

PCB的E-CAD设计工具能一个这些功能的一个整合,这是人们非常感兴趣的。此功能使客户为在PCB支付的费用大大减少,在某些情况下,节省的费用很容易超过10%!(某些情况下,甚至更多),而且在浪费和能源消耗(包括对生态环境的影响)方面比人们估计的占比世界PCB市场(约>600亿欧元)的百分之几要少得多。在考虑了整个的电子计算机辅助设计PCB设计工具的用户数量,这将对整个电子世界产生巨大的影响。减少因辅助铜线不合理所产生的额外成本和浪费,这是PCB的E-CAD设计工具最伟大的一个功能!!

" CEC’s use of the Elsyca software has helped to accurately predict the needed plating parameters to increase our first pass yields on new parts. "

Elden Hendrickson

Calumet Electronics

" Copper balance and thickness uniformity reduces scrap rate and improves yield. Nowadays with advanced technology, such software is strongly recommended "

Ghassen Dhaoudadi

" Copper balancing should be done, not only at the panel level in PCB FAB, but every PCB designer should be taught the many benefits of copper balancing and incorporate the concepts into their board designs "

Rick Hartley

" Elsyca software helps us a lot to identify critical areas already in the design phase. But we also can use it on the shop floor to support our Engineers to predict how different set ups of designs and parameters influence the outcome. Due to this fact we can reduce the amount of trials which also leads to cost reduction. "

Sabine Liebfahrt

AT&S

You might also be interested in

Looking for more information?

Don't hesitate to contact us!