Discover our complete solutions portfolio covering Cathodic Protection and Corrosion management - PCB design and plating - Functional and decorative plating - Electrocoating - Acoustics

Discover Protect

Elsyca V-PIMS

A revolution in digital PIMS combining Pipeline Corrosion Integrity Management System (PIMS) and computational modeling capabilities

Elsyca IRIS

Deep analysis of AC threats supporting efficient mitigation systems computer-aided design

Elsyca CatPro

Graphical simulation platform for cathodic protection and DC stray current analysis of pipeline networks

Elsyca CPManager

3D CAD-based software simulation platform for the computer-aided design and analysis of cathodic protection installations

Elsyca ACTA

Unique solution offering accurate, disambiguated, and tailored risk ranking report of pipeline networks

Plate

Elsyca PlatingManager

Leverage a digital twin of your plating line to predict plating performance and increase manufacturing capacity

Elsyca PCBBalance

The world’s only PCB DFM software that applies automated and optimized copper balancing to your PCB design and panel layout.

Elsyca PCBPlate

State-of-the-art graphical simulation platform for enhancing the plating performance of your PCB panel and pattern plating processes.

Elsyca ECoatMaster

CAD independent software platform for the simulation of the automotive electrocoating process of a body-in-white (BIW).

Elsyca EPOS

Simulate the performances of electropolishing processes based on a virtual mock-up of the electropolishing cell.

Elsyca AnodizingManager

State-of-the-art graphical simulation platform for analyzing the production performance and quality of anodizing processes.

Innovate

Elsyca CorrosionMaster

CorrosionMaster identifies corrosion hot spots and predicts corrosion rates, enabling engineers to look at alternative material combinations and/or coating systems, or investigate corrosion-mitigating measures.

Elsyca LeakageMaster

Improve vehicles interior acoustic comfort by performing upfront virtual smoke tests.

Elsyca MeshingMaster

Automatically creates meshes for a variety of applications such as acoustics, CFD, thermal analysis, etc

Elsyca XPlorer

Interactive simulation results viewer for Finite Elements results

Elsyca XPlorer3D

Analyze, Understand and Get Immersed in your results

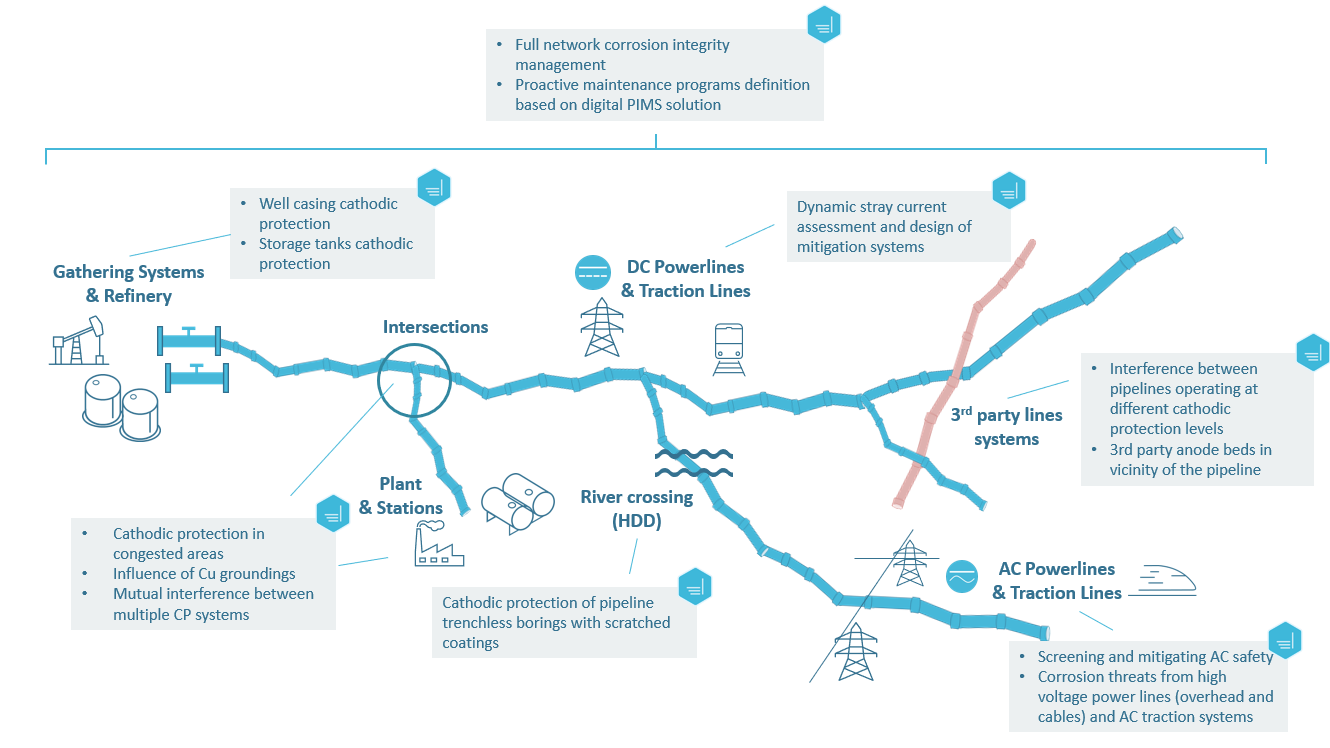

Pipeline Networks

Avoid business disruption by developing the most effective corrosion-prevention strategies for your entire network

A new way of managing corrosion over entire pipeline networks

Shifting to a proactive maintenance mode

With corrosion being responsible for one-third of the pipeline incidents, asset owners can gain competitive advantages through cost-effective maintenance programs ensuring business continuity of their assets.

The investment in Elsyca's solutions finally makes possible the lowering of the total cost of ownership by allowing assets owners to:

- develop efficient pro-active maintenance programs minimizing costs of surveys and repairs and loss of production risks;

- develop intelligent risk-based inspection programs by knowing the impact of changing conditions along the pipeline routing;

- connect the dots between discrete readings;

- endorse interoperability between corrosion, integrity and reliability teams.

We are developing the future of corrosion integrity management with digital twin solutions that combine real-world field data with deterministic 3D models of the assets for quantitative risk assessments

Accelerate Interoperability

Corrosion Team

- Optimize ECDA programs;

- Define strategic locations for continuous monitoring devices;

- Reduce field inspections and maintenance of test stations;

- Predict anode bed replacement;

- Improve your Cathodic Protection (CP) system designs & effectively design AC and DC mitigations;

- Reduce your dig and repairs.

Integrity Team

- Translate potential measurements into actionable corrosion growth rate results;

- Develop risk-based approach;

- Reduce overall risk by an improved corrosion control;

- Redefine ILI inspection intervals;

- Increase your knowledge on root cause of corrosion attack;

- Refine your dig locations at joint level.

Reliability Team

- Monitoring of CGR for accurate MAOP updates;

- Better insight in corrosion prevention performance;

- Identifying critical systems, their sensitivity on integrity performance;

- Propose system improvements for increasing pipeline safety.

Relying on physics rather than statistics

Learn how Elsyca V-PIMS puts science at work to help pipeline operators to define the most effective proactive maintenance programs, reduce costs of repairs and minimize production losses due to corrosion.

A complete solutions portfolio for

full network corrosion integrity management