Elsyca V-PIMS

A revolution in digital PIMS combining Pipeline Corrosion Integrity Management System (PIMS) and computational modeling capabilities

More InfoDownload file

Mechanistic modeling to deliver breakthrough for corrosion protection of pipeline networks

Integrity management of complex pipeline networks becomes increasingly complex because of ageing structures, network expansions and tendency of shared collocations with electrified third party systems leading to accelerated AC/DC corrosion.

Today’s conventional field surveys and remote monitoring devices have their technical limitations facing the pipeline integrity engineer with the tremendous amount of data making timely decisions almost impossible. While long-term trending is typically handled by statistics, today’s industry calls for a more sensitive and responsive risk assessment of acute RMU alarms or sudden change in data patterns and root-cause analysis of identified ILI anomalies.

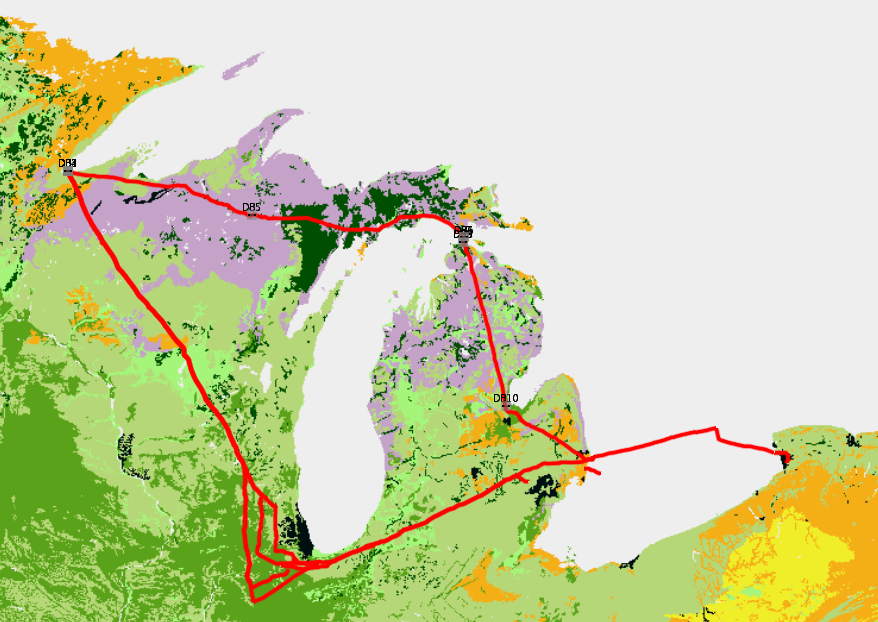

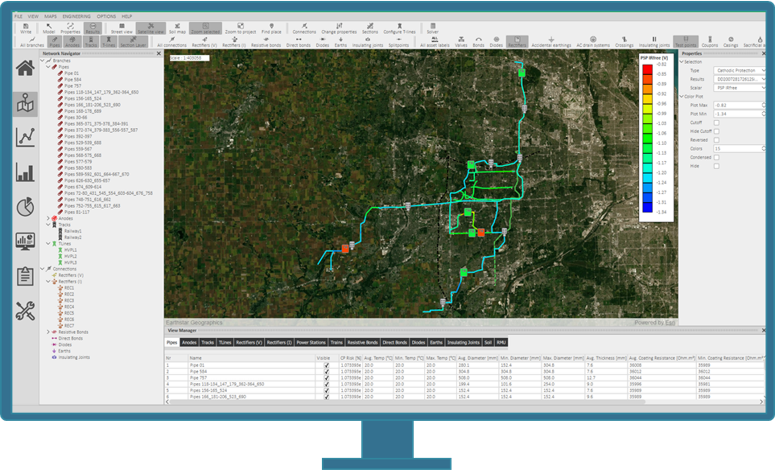

Elsyca V-PIMS, a novel GIS- based simulation software, computes the corrosion health condition of the company’s pipeline network providing unmatched quantitative insights in the big data stream.

Unprecedented insights

- Fast (<min/mile) access to corrosion rates, corrosion origins, and metal losses based on field data at any point of the network;

- 99.9% accuracy in identification of critical locations;

- CP protection levels and AC/DC current densities anywhere on the network;

- Analyze the impact of pipeline events, predict mitigation performances and impacts of threats (AC/DC interferences);

- 300% to 400% reduction in leaks and corrosion attacks;

- Access to metal losses anywhere on the network.

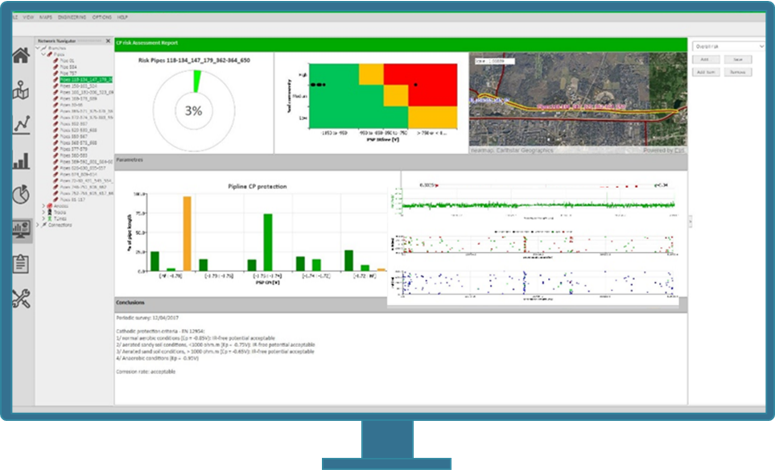

Simplified analysis and reporting

Leverage the embedded GIS platform to easily visualize results and field data. Automate compliant pipeline network corrosion dashboard based on user-defined key performance indicators (KPIs).

- Forecast corrosion prevention costs for new, aging, and acquired pipeline systems;

- Proactively plan inspections and maintenance;

- Vizualise field data with powerful graphics and correlated with other field data and/or simulation results;

- Support re-assessment intervals in ECDA programs;

- Empower interoperability in-between integrity and corrosion management teams.

Elsyca V-PIMS

Solution deployment

Model

- Complete pipeline network model with granularity at the joint level;

- Operating cathodic protection and mitigation systems;

- Field data;

- External threats (power lines, transit systems, and 3rd party pipeline representation)

Enrich & Calibrate

- Retrieve coating conditions based on measured ON potentials;

- Input local soil corrosivity characteristics;

- Input polarization behavior curves.

Analyze & Report

- Monitor true protection level;

- Troubleshoot the cathodic protection of the network;

- Computer-aided design mitigation solutions;

- Study what-if scenario’s;

- Develop PIMS intelligence.

Key Benefits

Reduce risks

Identify high-risk areas to prioritize field surveys or to decide where to install remote monitoring devices. Discover field data anomalies without delay. Easily adapt the CP system for any change in environmental conditions. Do all this using Elsyca V-PIMS embedded and comprehensive corrosion dashboard.

Maximize CP performance

Get quantitative insights into the CP performance. Investigate upfront all options for new installations, extensions to the existing infrastructure, or changes in the pipeline configuration. Select the options that maximize CP performance.

Stay in control

Import field survey results and data from remote monitoring units. Perform an analysis of the severity and consequences of the reported alarms. Explore what-if scenarios and investigate corrective actions before undertaking costly field operations.

Mitigate interference effects

Identify and investigate AC/DC interference from neighboring structures. Research and numerically model solutions that mitigate interference effects, even for the most complex situations that can arise in highly congested areas.

Key Features

A wide range of functionalities

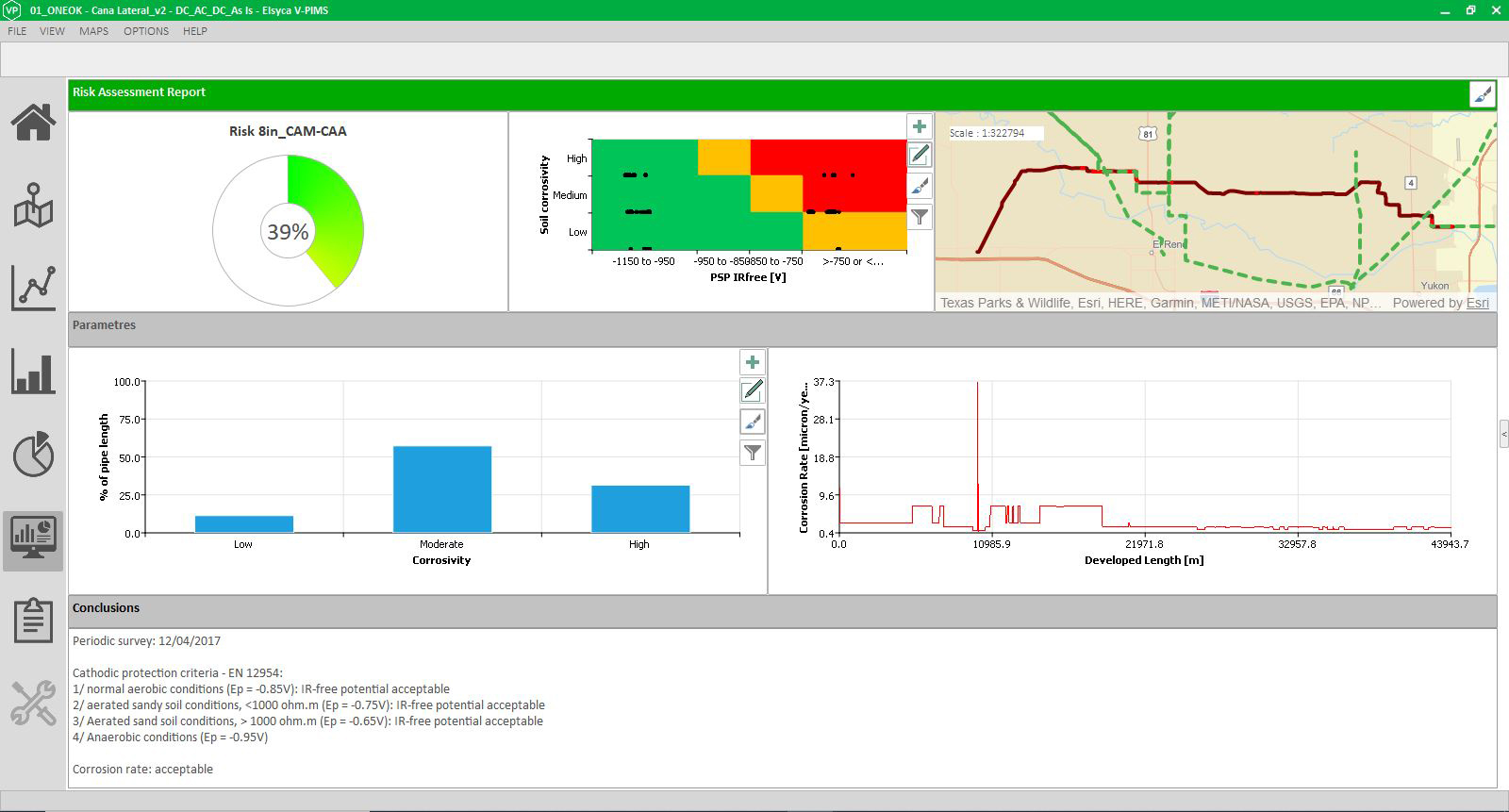

Quantitative corrosion analysis

Elsyca V-PIMS calculates the current flow and potential distribution throughout the pipeline network. The impact of any corrective measures defined in the Elsyca V-PIMS model can be evaluated through the related change in corrosion rate, delivering quantitative insights well before implementing any measures in the field.

A comprehensive database

Data related to the main factors impacting pipeline corrosion (coating properties, soil conditions, CP system parameters, etc.) are accessible in different layers of the Elsyca V-PIMS database. Having this database linked to a GIS model provides immediate access to all relevant parameters in any critical zone identified on a digital map.

Easy access to field data

All remote field data that have been captured over time are available in the Elsyca V-PIMS geospatial database. The related GIS model is built on data of the pipeline, CP system, high voltage power lines, electrified systems, foreign pipeline systems, etc. which enables visualization of corrosion health status & CP effectiveness on a digital map.

A validated network model

Well correlated with measured field data by Elsyca experts, the Elsyca V-PIMS mechanistic model confidently describes the actual status of entire pipeline networks. By generating IR-free potentials and current densities along the pipeline, a quantitative and realistic assessment of corrosion risks is provided throughout the network.

Root cause analysis

Elsyca V-PIMS builds an intelligent model from the geospatial database. Soil properties are translated into polarization data and attributed to pipe sections. Coating conditions are assigned to pipeline segments. Material grade and diameter are considered for attenuation calculations. Rectifier bonds are created. Elsyca V-PIMS then performs the calculations that enable a root cause analysis of corrosion anomalies.

AC/DC interference analysis

Starting from the model describing the “as-is” status of the network, Elsyca V-PIMS predicts steady-state and fault AC interference effects from high voltage power lines, as well as DC interference from electrified systems or foreign pipelines.