Tooling design for electroforming of dashboard mold

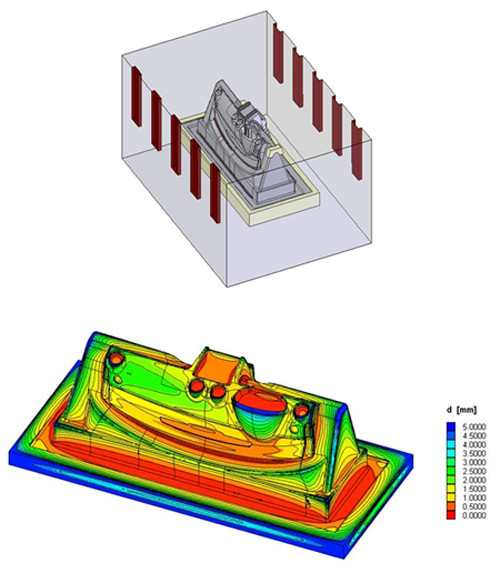

For large size parts to be electroformed, as for example a dashboard mould, the first step of a Computer Aided Engineering project consists in a fast plateability analysis, based on the CAD of the mould and the tank configuration with its main anodes.

For large size parts to be electroformed, as for example a dashboard mould, the first step of a Computer Aided Engineering project consists in a fast plateability analysis, based on the CAD of the mould and the tank configuration with its main anodes. This analysis reveals the deposit thickness distribution that could be achieved by only using the main tank anode baskets and by consequence also provide a first indication on the amount of reworking efforts that will be required for electroforming this part within thickness specifications if no extensive use is made of a dedicated tooling system.

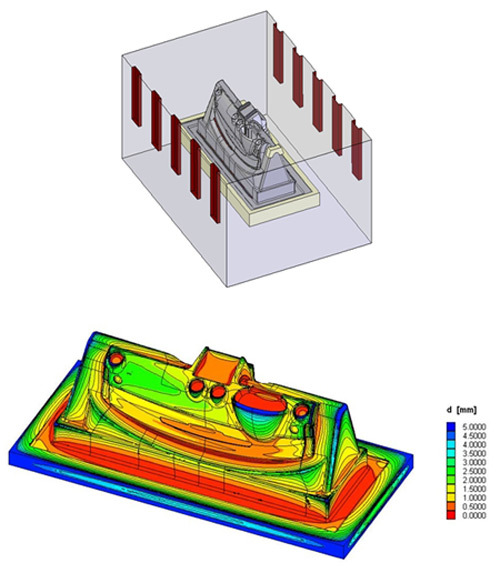

By addressing each problem zone at a time via iterative simulations, a complete configuration of auxiliary anodes, current robbers and insulating shields is gradually developed. Different rectifiers act on separate conforming anode groups in order to achieve enhanced control over the current density distribution. This finally leads to a nickel deposit thickness that is within specifications for over more than 95 % of the surface area to be plated.

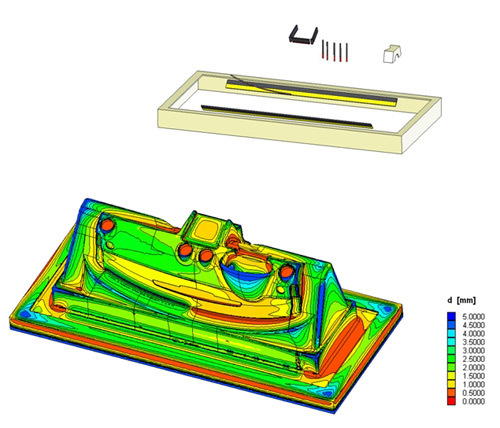

Below a partial tooling set is show, comprising some dedicated solid nickel conforming anodes and a few insulating shields. The resulting performance as simulated for this partial tooling set, being used in combination to the main anode baskets (= hybrid operation modus) and after fine tuning the process parameters (current imposed through the different rectifiers) indicates that already a significant improvement has been achieved.