Design Plateability Analysis for precious metal jewelry

For jewelry often the entire surface area has to be gold plated within minimum thickness specifications and maximum alloy content specifications.

For jewelry often the entire surface area has to be gold plated within minimum thickness specifications and maximum alloy content specifications. Hence no distinction between A, B and C type surfaces can be made (in contrast to most decorative chrome plating applications).

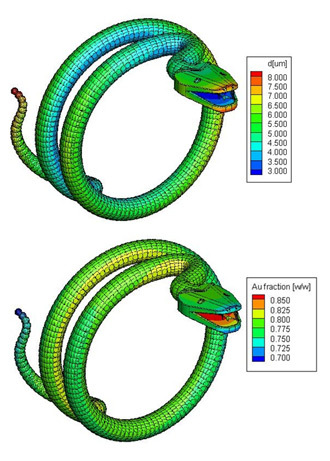

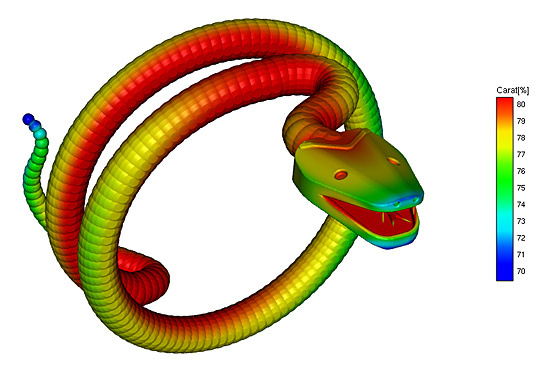

For larger size jewels with a complex shape like the snake bracelet, a plateability analysis indicates that it is practically impossible to plate (or electroform) the entire surface area within specifications by using only the main tank anodes, unless the part is largely overplated. The color plots show that, although the average plated gold layer thickness is 5 micron, an important fraction of the surface does not meet the 4 micron minimum spec. Also, some protruding edges (tail and head of the snake) do not meet the 18 K (= 75 w/w percent) gold content specifications.

The results from a plateability report are delivered to the customer in document format containing the different global result data in tabular format and color plots for the deposit thickness and alloy content (K)

Result files are also made available in numerical format through the Elsyca data server for visualisation by means of the Elsyca Xplorer viewer.