Revolutionizing EV battery tray protection

Unveiling the power of Computer Aided e-coating engineering

EV battery tray: A key component to protect

Regardless of their categorization as packs, boxes, or trays, these structures housing EV battery cells, alongside their electrical and thermal management components, are crucial in the EV industry. Enhancing battery packs involves various decisions in manufacturing and materials, ensuring safety, and addressing design challenges. One challenge is applying a durable acid-resistant coating to battery trays and power backup systems, serving to provide electrical insulation and resist acidic substances.

With the increasing EV numbers, there's a growing demand for specialized coatings and components to ensure functionality and safety without compromising performance. Since approximately 40% of an EV's cost is in its battery, safeguarding it with suitable coatings is crucial for longevity and efficiency.

Enhancing longevity and efficiency via electro-coating

To achieve this, dielectric coatings are applied via an electrophoretic process known as e-coating. E-coats, in liquid form, are contained in a bath where positively charged coating material adheres to negatively charged parts due to electrostatic attraction. E-coat systems are valued for their durability, ensuring consistent coverage of intricate parts with high productivity and minimal waste. They are particularly effective for large-scale production components like lids, trays, frame plates, and module racking. However, e-coating may encounter challenges such as uneven thickness and compatibility issues with substrate materials, as well as comparisons with more environmentally friendly alternatives. Understanding the process, tweaking parameters, and overcoming obstacles enables manufacturers to maximize e-coating's potential, enhancing production and product quality.

The Computer Aided Engineering (CAE) approach is invaluable for optimizing e-coating process performance. CAE utilizes predictive computer modeling to assess process quality before production, reducing the need for wet testing and streamlining iterations. It identifies process risks and limitations early in the design stage, ensuring superior coating quality. Overall, adopting CAE offers significant benefits in terms of cost, precision, innovation, and sustainability, making it an essential tool in modern engineering practices.

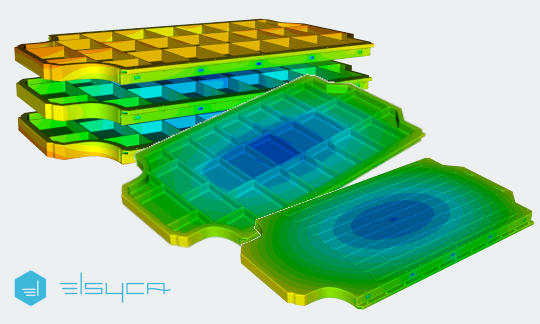

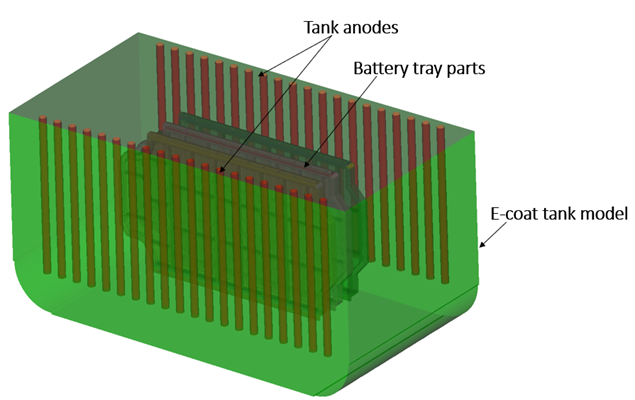

The Elsyca ECoatMaster tool, an advanced graphical simulation platform developed in-house, conducts e-coating CAE. It utilizes a digital twin model of the e-coat tank setup, comprising a 3D representation of the processed part, tank configuration, process parameters, and paint solution. Using Finite Element Analysis (FEA), the Elsyca E-CoatMaster calculates current density distribution and paint layer thickness based on Faraday’s law. Detailed information on paint layer thickness distribution and quality, including under- and over-coated areas, is available for each part on the flight bar.

Getting relevant insights

These simulation results boast high accuracy, validated against field measurements. This accuracy stems from thorough electrochemical analysis of the paint solution, providing invaluable insights into its performance. Additionally, the optimal process operating parameters are determined, ensuring desired surface quality while preventing deposit defects like inadequate coverage.

Improving the process

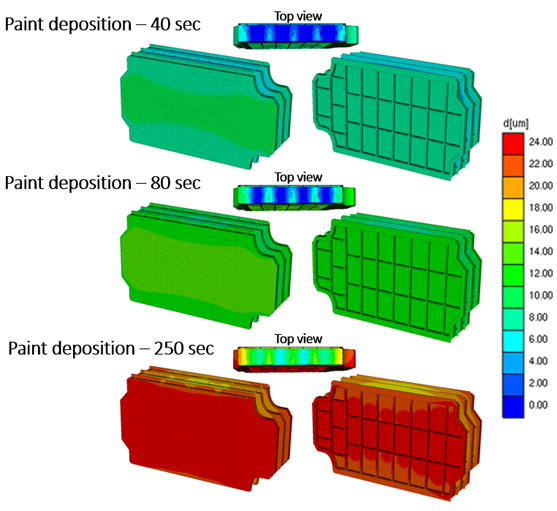

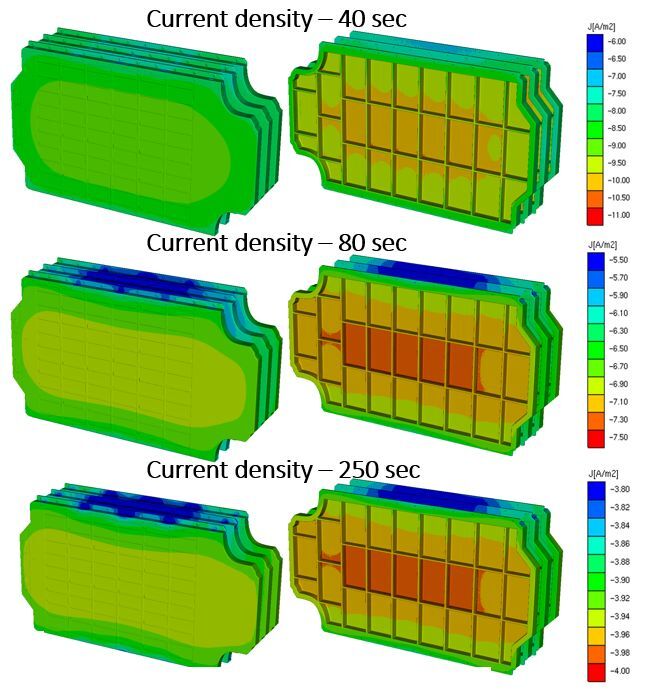

This technology has been utilized to evaluate the performance of the e-coating process for EV battery trays, focusing on current density and paint layer thickness distributions. Figure 2 depicts the paint layer thickness distribution over time, with color-coded mapping highlighting disparities in thickness—blue indicating under-deposition and red indicating over-deposition. Figure 3 showcases the distribution of current density, highlighting areas with varying densities on the e-coated parts. This analysis uncovers apparent quality issues in the e-coating, suggesting room for improvement. Tailored optimization strategies can be implemented by refining the process scenario and iterating simulations to address these issues effectively.

Further reading:

You might be interested reading the full case study: Revolutionizing EV Battery Tray Protection