Elsyca ECoatMaster

Upfront assessment of e-coat process performances

More infoDownload file

Electro-coating Simulation made simple

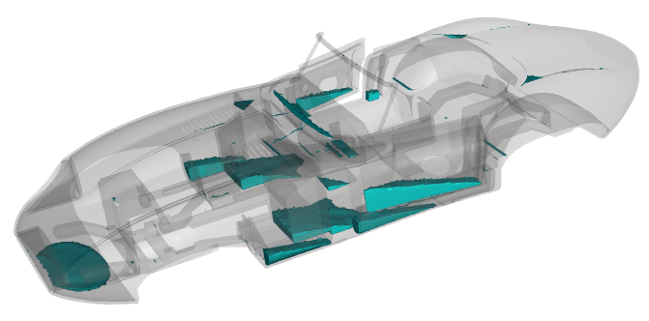

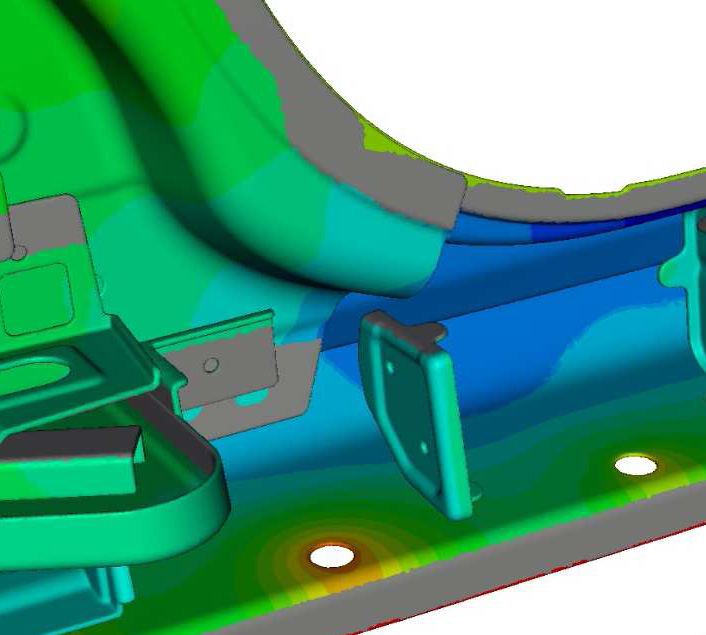

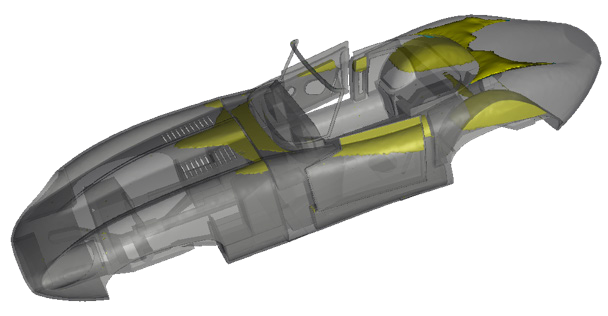

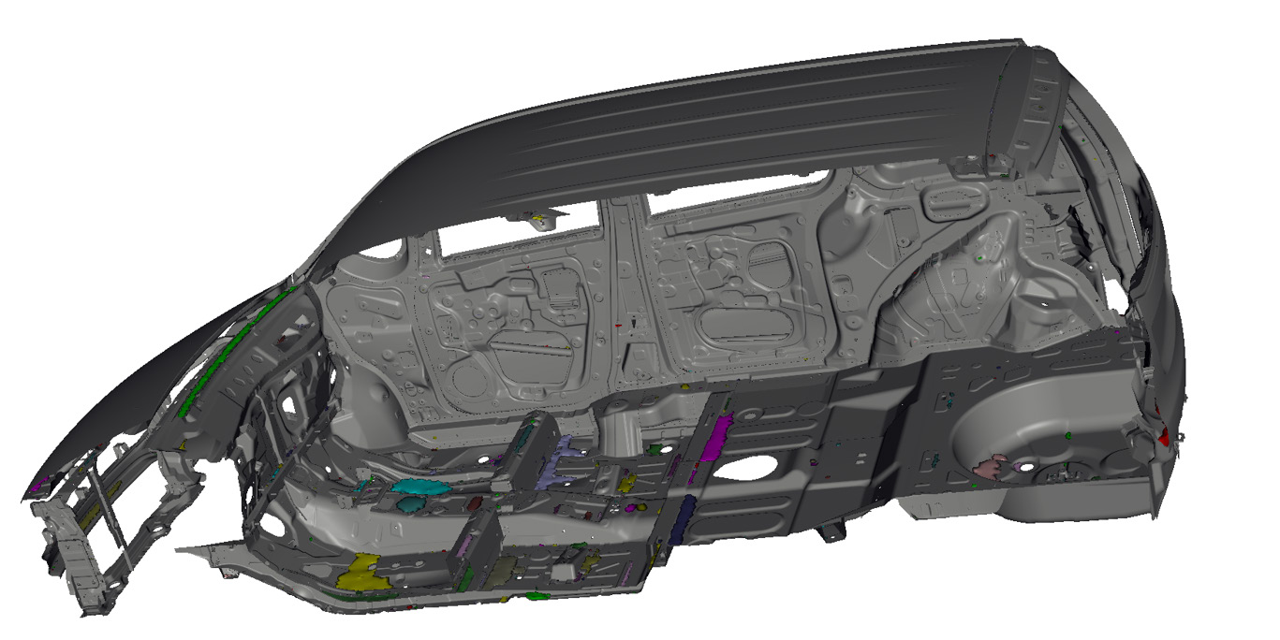

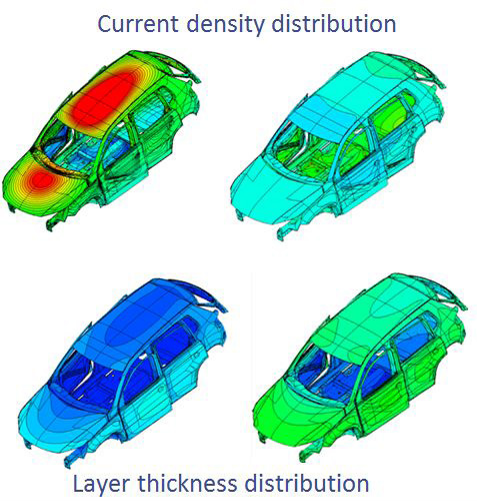

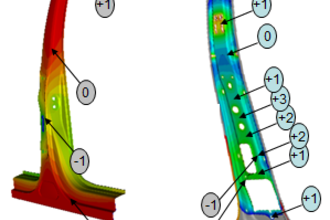

Elsyca ECoatMaster is the virtual representation of the e-coat step in your production line. The tool predicts current density and deposited paint layer thickness distribution based on the virtual configuration of your e-coating line and the CAD model of the body-in-white. Identification of the surface risk areas and validation of the impact of design modifications and/or changing process parameters have never been that simple.

With Elsyca ECoatMaster, the automotive corrosion engineers should no longer rely on expensive prototype test runs or on sub-optimal simulation tools that do not provide accurate results in a reasonable process time. In case of conflicting requirements (e.g. adding a hole in the interest of electro-coating may conflict with crash requirements), Elsyca ECoatMaster becomes an indispensable tool to substantiate design changes.

Key Benefits

Quality

Identifies potential production issues at the design stage, ensuring the paint thickness specifications are met on all exterior and interior surfaces of the vehicle.

Time-to-market

You can simulate the e-coat process even before the first physical prototype enters the building. The analysis can start as soon as the BIW’s CAD data is available, providing ample time to modify the design and speed up production.

Cost & Warranty

Ensures a top quality e-coat performance from the start, avoiding expensive production tooling

changes and warranty issues.

Gain Knowledge & Save time

ECoatMaster is an investment in knowledge as it helps to build and retain critical company know-how. Impact of new e-coat paint or new line designs can be verified, without the need to access

the physical production line.

Key features

A wide range of functionalities

Import and prepare your model in just a few clicks

Simply export your model from your favorite CAD platform and import the STL files into Elsyca ECoatMaster. It is indeed as simple as that!

Tailored to your infrastructure

Your existing or planned e-coat lines can be defined, including RoDip lines. Define process parameters such as vehicle trajectory, material, paint data, flow regions, anode voltage programs, etc…

Quickly compare paints

Easily and quickly compare and validate new paints without any previous calibration step

Consideration of liquid drag over and gas traps

Elsyca ECoatMaster automatically computes liquid drag over and potential gas traps affecting the final quality of the coating thickness.

Embedded Mesh generator

Do not worry about the generation of your model preparation. Starting from the CAD model, Elsyca ECoatMaster generate the required mesh ensuring final results quality

Visualize and Share results

Supported by Elsyca Xplorer, Elsyca ECoatMaster results can be easily visualised and shared with other stakholders.