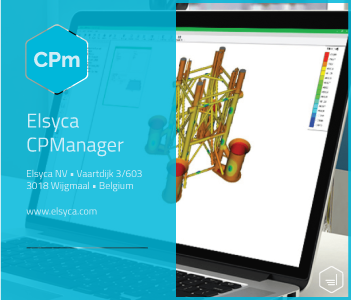

Elsyca CPManager

Cathodic protection to perfection via computer-aided solutions

More infoDownload file

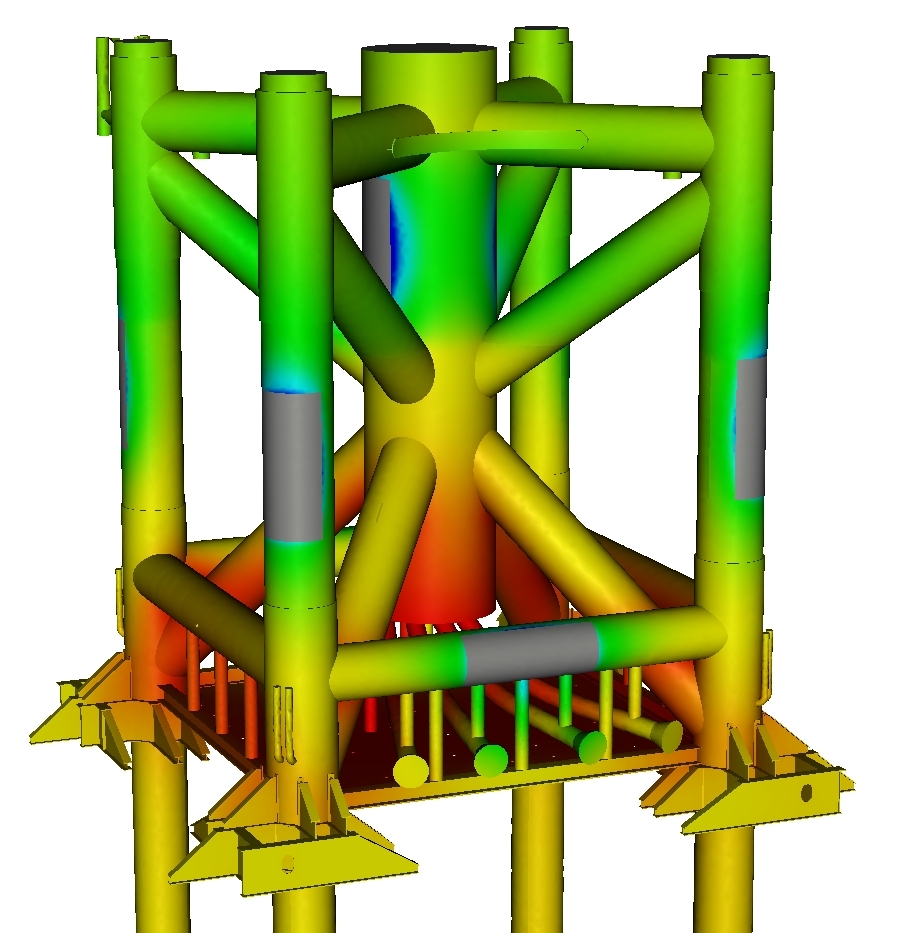

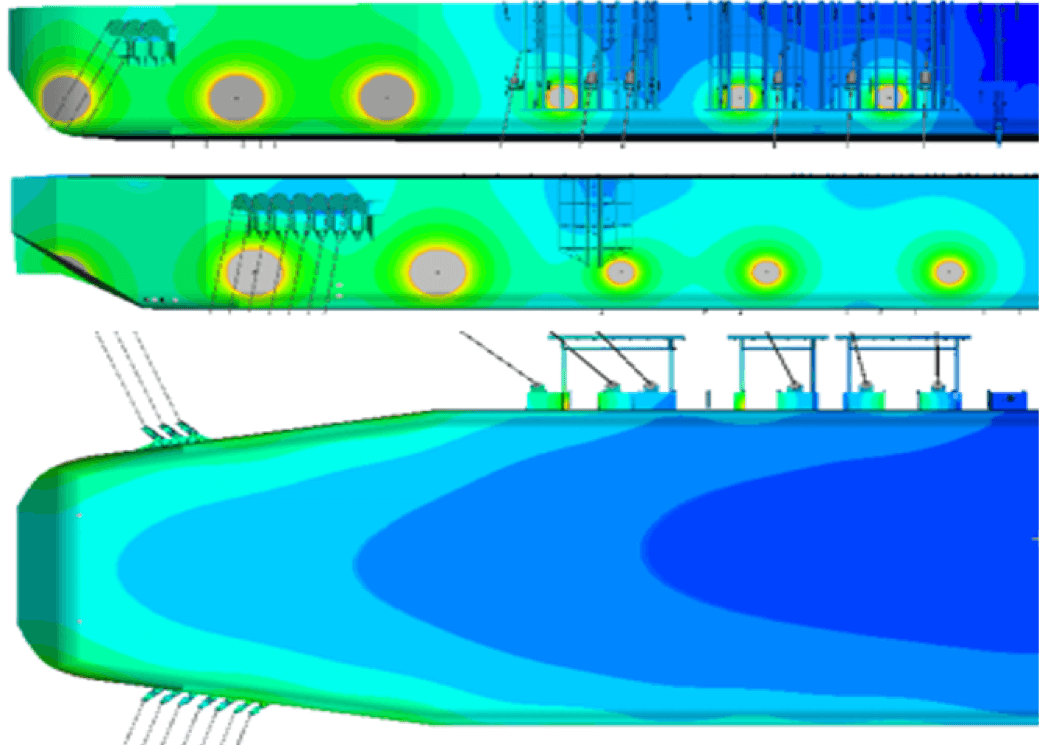

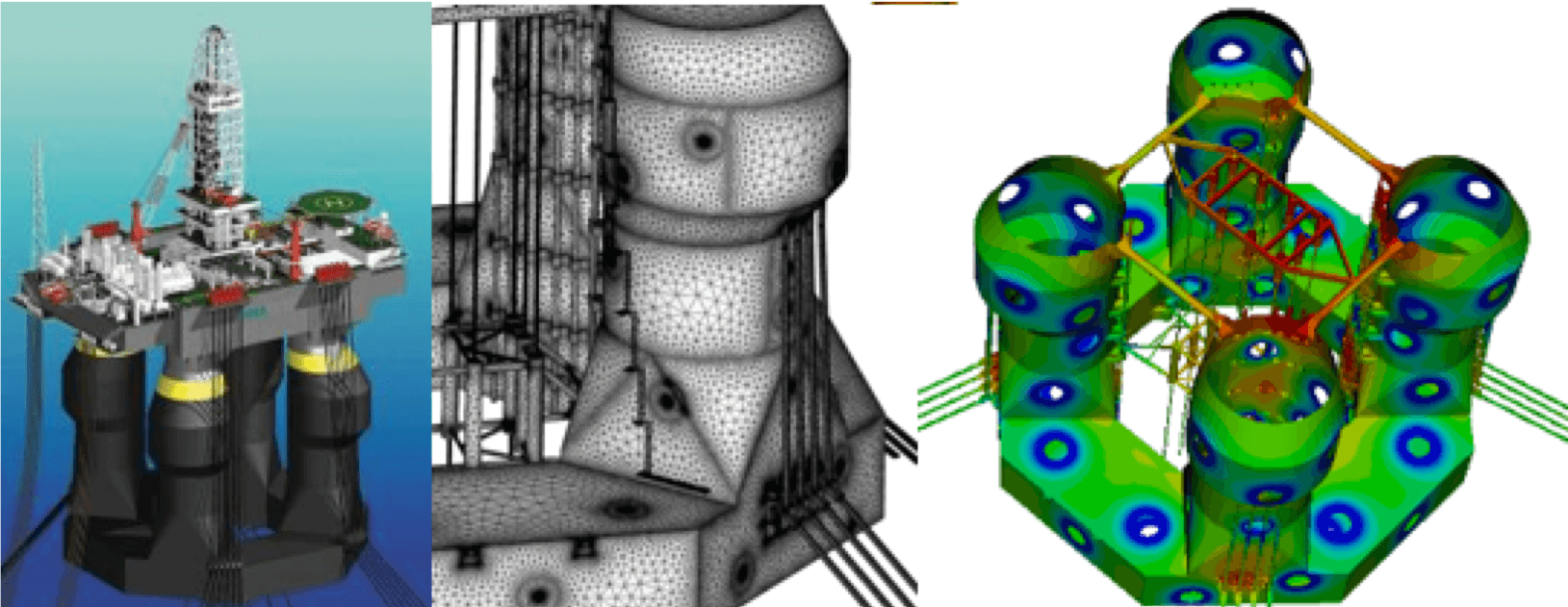

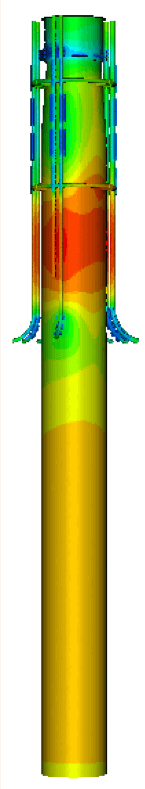

On- and Offshore CP Computer-aided Design

Elsyca CPManager enables the corrosion engineer to develop, assess and verify CP designs or grounding systems of any on- or off-shore construction in compliance with international standards, ensuring optimal operational performance and avoiding costly retrofits.

Elsyca CPManager simulates the performance of Cathodic Protection installations and provides detailed information on the protection level of the invaluable constructions to be protected. Ingenious in its simplicity, no CAD or meshing skills are required. As a user, you just import the geometrical information from virtually any CAD environment, select material/environment polarization data and electric network, and start the simulations. It really is that simple!

Key Benefits

Save time, reduce stress

CP installation can be virtually modeled and validated long before the structure is built or the retrofit is implemented on the physical structure. Avoid costly and stressful surprises and buy yourself some peace of mind.

From supplier to valuable partner

Become a value-adding partner for your clients ... use the simulation to discuss cathodic protection choices and to argue your strategy based on science. At the same time, you build up knowledge by using intelligent simulation software, enabling you to enhance your overall service level.

Improved Cathodic Protection Installation

Visualize the risk zones on the structure and adapt your cathodic protection installation accordingly. On-time delivery of a properly computationally designed and validated CP system leads to a satisfied customer!

Reduce cost & time

Avoid physical trial and error and unnecessary high installation costs. Anticipate future modifications… it all ultimately leads to meeting and exceeding client expectations and higher profits for your company.

Key features

A wide range of functionalities

Seamless integration with CAD

Seamless integration within SOLIDWORKS® for CAD modeling;

Automated mesh generation

High-quality meshes will be generated without any user invention. The software includes technology to heal problems in the STL file that would otherwise prevent the creation of a volume mesh.

Support international standards

Current demands and coating breakdown according to international standards such as DNVGL RP B401 and EN 12954, NACE SP0176 and NACE SP169.

Full support complex environment

Multi-layered soils, calcareous layer growth, Ohmic drop effects in the soil/water, anode consumption & shape change,… are all available at your fingertips.

ICCP or SACP

Full support of impressed current and/or sacrificial anodes and hybrid systems design. Can also be used for the analysis of freely corroding structures and grounding system performance.

Reliable results in a few minutes

Robust and fast solver calculating structure-to-soil or structure-to-water potentials, electrolyte potentials and current densities.

Convenient to share and collaborate

Automated reports are created at the end of the simulation.

3D results visualization

Interactive 3D visualization in other Elsyca solutions such as Elsyca XPlorer or virtual reality solution for comprehensive analysis that can be shared with third parties.